Voltage is 52V at the batteires but only 38V at the Victron Multi input. The 35mm2 cable should be big enough but it's old, maybe corroded (?), could that cause this?

- Home

- Anonymous

- Sign in

- Create

- Spaces

- Grafana

- Node-Red

- Unsupported topics

- Questions & Answers

- Modifications

- Communauté francophone

- Deutschsprachiger Bereich

- Preguntas en Español

- Explore

- Topics

- Questions

- Ideas

- Articles

- Badges

question

What happened to this cable?

Hard to tell by simply looking at a photo but it appears there might have been a sharp kink made in the cable or pinched somehow possibly breaking several strands causing the wire to get very hot at that point and melting the jacket. Don't know for sure but just a guess on my part.

Yes, completely agree I have seen a lot of this in my servicing life.

But also suspect this cable might have been (fatigue) bent a few times in the area of damage causing work hardening, happens in wires just as it does in metal strips, this in turn will cause a higher resistance causing a heat build-up in that area.

It's a fire risk. Replace asap.

It's not clear what the the other black wires are, but a big stack inside the switch may have resistance issues. Better to use a busbar.

If you regularly use the rotary switch, especially under load, you may have damaged the contacts through arcing. Best to check its resistance and replace if necessary.

@Ian0 and @regman54 and. @kevgermany definitely have valid points.

The black underneath should be the second insulation level. If it isn't then that corrosion is really bad and then the cable is wrong.for the application.

Several things to note.

Cable was hot very (obviously). But should have been able to handle the heat if it was an up to standard cable. Causes of heat - bad torque, poor crimp (under crimped) or over crimp so the cable actually became smaller than the recommended 35mm².

The other cause is not using fine strand wire. (Standards again)

If it split there, it could have been damaged insulation damaged during handling and install. Or the cable is not actually up to specifications especially the heat rating (which is very likely the insulation should handle 100s of degrees before smoke) and use of actual copper.

If the corrosion is that bad, then it probably started as a compromised/poorly stored cable. Which means it should not have been installed in the first place. The other thing I have seen on cheaper cable is it is not actually copper... So check that too.

If you have to stack lugs, put the one with the highest power first on, then the others.

Then put a washer on and a springwasher (or however this is called in english) and then the nut.

But as @Alexandra mentioned, for security reason use a Busbar.

However, PVC cables starting to give up at 60°C and are gone at 80°C.

Better is the use of welding cables H01N2-D (do not use the -E, because they are much more flexible of finest strands, but if you do not have the right tools, you endup in a nightmare)

In addition to the excellent points already made, I'll add that the rotary switch you're using isn't rated to the system voltage you're using it on... No readily-available rotary switches are rated to 58-60V as required for a 48v nominal system.

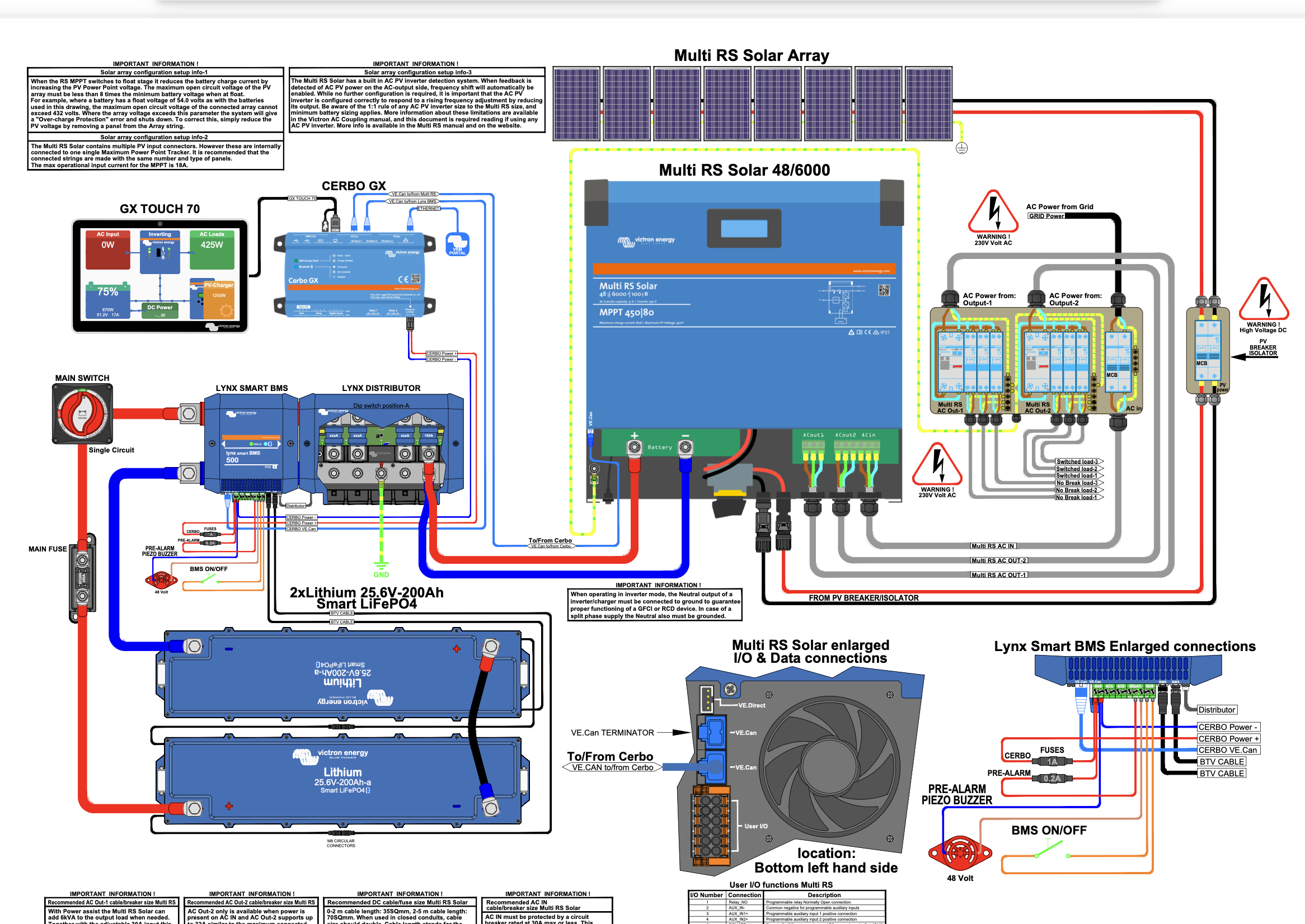

I was told on this forum that this switch is "of course" compatible with 48V systems. Also Victron writes that this switch is for up to 48V systems. Victron also use this switch in their Multi RS drawing with 2 x 25.6V batteries. Why would Victron recommend this switch for the Multi RS if it is actually max 48V?

100% heat damage and it doesn’t look like it’s started from the switch bubbling on the cable or sleeving if that is sleeving, if not I would say the connection to your multi isn’t great as the heat has generated at that end hence bubbling multi end and the discolouration of the insulation that’s if it is not sleeved!

What multiple are you running?

The heat definitely, IMHO, came from the switch end.

@Craig Chamberlain could Be but would like OP to show the connection in the multi and exactly what multi it is for the and if the two black cables are also feeding to the multi, but either which way think everyone’s consensus is not to run the system at this point and maybe to bottom out the cause. @nick5000

I'm very interested in seeing the cable sawed in halves, to see wether it is copper-clad or real copper.

is it possible to know wether it was new for this application, or was this normal cable used before (wrongly) in a cable-chain and ended months later in the trash-box. After that it was picked up and misused/reused again. Mechanical dead, overburdend with heat by lug stacking. Maybe 10 iD lug on 8mm oD screw above smaller ones from the black cables.

Thanks for the replies! I didn't get any email confirmation for the replies, so didn't see all the replies until now.

The cable was an older cable that the installer said was ok. I checked it now and it is brittle and make cracking sounds when I twist it, so I guess this cable is not very good. Also the connection to the Multi was small and poor and looks black. I think it started happening when we connected to shore power for the first time recently, and got around 5000W in together with solar at the max. I'd set max charging to 100A.

I've already replaced this cable, and will also look over all the other cables (and will also avoid charging at 5000W which I don't really need to).

If you haven’t replaced the switch at least i hope you cleaned the contacts don’t answer my previous question as you answered here. Still IMO I would worry about the volts it’s the amps but the lug looks like it hasn’t got any meat on it to me which would 100% cause buildup of heat which just leads to more resistance and heat until this happens. Is the cable copper clad and by any chance was that lug soldered? As I would say they are looking like the cause as I see what looks like solder in the cable and on the edge of the lug. Is this the case @nick5000

Spot on to everyone that said switch end, I stand corrected Sir’s ;)

It would be a good idea to keep a close eye on temperatures until you're happy the problem is fixed. That switch is clearly suspect.

Related Resources

question details

48 People are following this question.