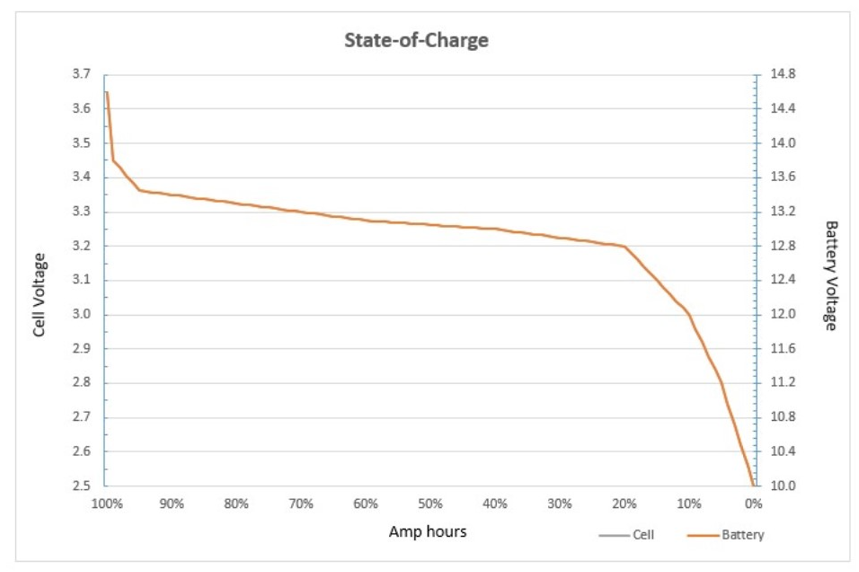

tl;dr - I have a Victron SmartSolar MPPT 100/50, a DIY 280Ah 12V LiFePO4 battery, and 450W of solar panels on my camping trailer, which gets used sporadically. My battery cell manufacturer (CATL) recommends keeping the battery SoC between 10% and 90% in order to extend the battery life. I've been fiddling with the Victron settings, but right now I'm finding it difficult to keep the controller from (over)charging the battery. Ideally I want bulk to charge as fast as possible at ~14.4V until I hit ~90% (when the SCC should switch from constant current to constant voltage) and then kick right over to float, but it seems like my SCC wants to charge my battery to 100% (or a bit more) regardless of what settings I use. Looking for advice on how to configure this correctly... more details about my setup below:

My camping trailer gets used one or two weekends per month, and then typically once or twice per summer for 2-3 weeks straight. Between those times it sits unused, and the typical parasitic draw of the BMS, SCC, SOC meter (Simarine Pico), propane leak detector, and radio is <100mA, which results in 1-2A of usage, if that.

When I use the trailer, our typical consumption is between 20A and 50A per day, depending on the weather and location. Sometimes we get full sun the next day and can recharge, but other times we'll go 4-5 days before we get any significant sun. In the latter case I've drained the battery to ~65% SoC before, which means the next day I travel I need to add at least 70A back to get to 90%.

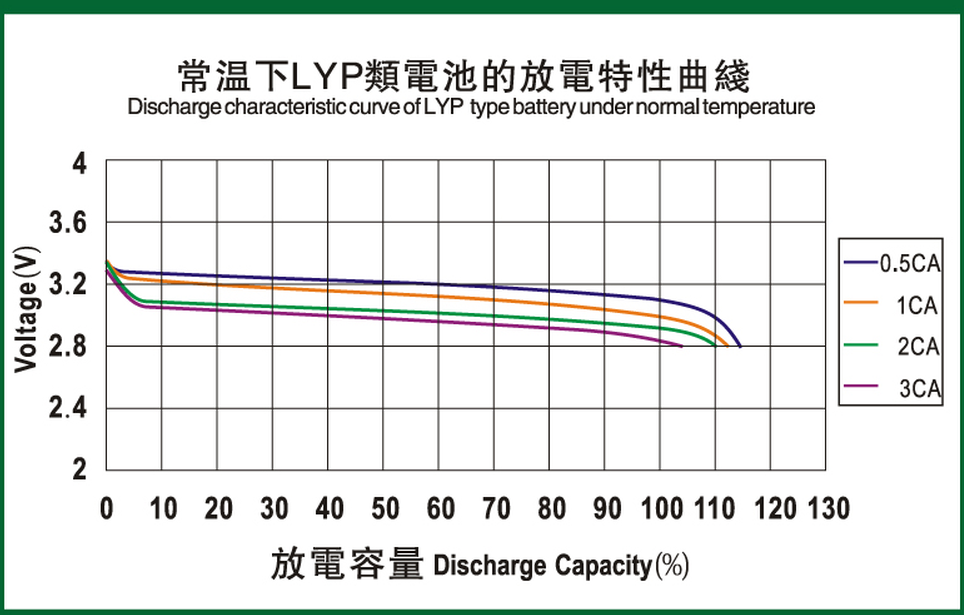

With my older Renogy Rover Elite SCC I found higher voltage settings significantly increase the charging current during bulk mode... to the point that if I set to 13.6V I might get a 1-2A bulk charge rate on a battery with an SoC of ~70% but at 14.4V the SCC was pushing 17A.

With the Victron I have NOT yet had a chance to drain my battery down to ~70% to see the result (planning to do this over Labor Day), but I have noticed that even when the BMS and SOC meter think the battery is 99%+ charged in the morning the Victron SCC will kick over into bulk mode and run that way for 6-8 hours before kicking into float. That makes no sense to me.

My BMS is set up for my CATL battery manufacturer recommendations:

low cut-off: 2.5V/cell (10.0V)

high cut-off: 3.65V/cell (13.6V)

balance: on

balance starts at: 3.4V/cell (13.6V)

Presently my Victron settings are:

absorption: 13.7V <- barely above cell balance voltage)

float: 13.2V <- intentionally below resting state of ~13.3V

equalization: disabled

re-bulk voltage offset: 0.10V

absorption duration: adaptive

max absorption time: 0 hours

tail current: N/A

Note that my LiFePO4 battery's resting state is about 13.3V. My goal with 13.2V float is that the battery does NOT get charged, but the SCC will power any parasitic devices. I think that's working ok.

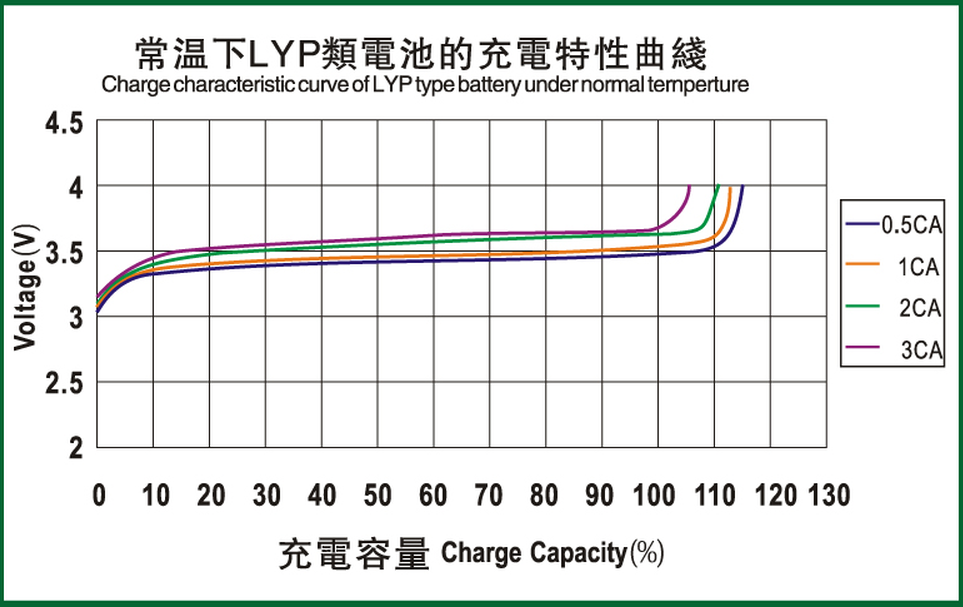

Also note I've set absorption to 13.7V since that *seems* to affect the bulk->absorption algorithm and I'm trying to prevent the SCC from continually charging a full battery right now, but ideally I want bulk to charge as fast as possible at ~14.4V until I hit ~90% (when the SCC should switch from constant current to constant voltage) and then kick right over to float.

Right now my Victron SCC seems to run in bulk mode pushing 1-2A for 6-8 hours, then goes into float. That seems wrong since I'm starting the day at >99% SoC with 278Ah in a 280ah battery (and TBH I'm not really clear if there's any "damage" being done by trickling current to a full LFP battery). It also seems wrong because at 99% I should be well above the point where the SCC can apply constant current... so in the morning right now (when basically idle) I'd expect the SCC to go right into float mode (or rather to go into bulk for a few seconds, then recognize we're at or above the CC->CV point and switch to absorption for 0 seconds, then go to float).

So as I said in the first paragraph, ideally I'd like a way to bulk charge quickly if (and only if) SoC is below ~90%, then kick over to float when I hit ~90% SoC. Otherwise I just want to float at a low voltage. Any help from those who have done this, or who understand the bulk charging profile better and can explain why this doesn't happen for me (at least when the battery starts off full in the morning)

Thanks