Hi Everybody,

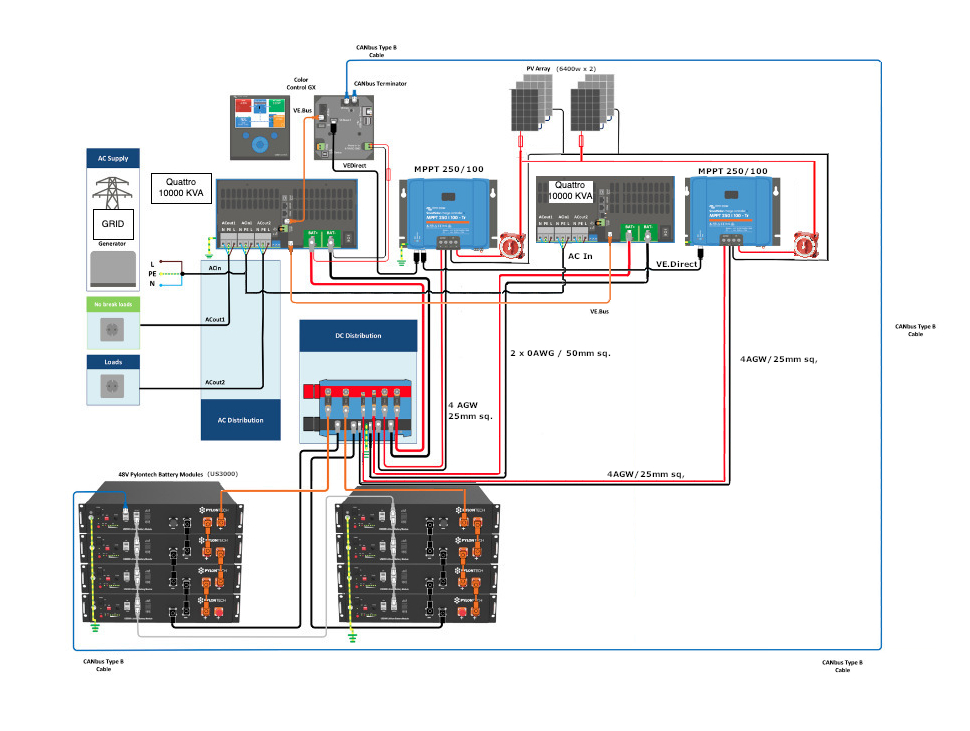

As it happens, my design is very similar to the example given by Victron in the Pylontech manual. The main differences are that I am using two MPPTs and two Quattros (instead of one MPTT and a Multiplus) and I have many PVs (up to 40 panels). So I have "stolen" the Victron schematic drawing and modified it accordingly. Now the questions:

1. Does the design make sense? It's for self-consumption. i.e use solar and batteries as the main source of power, with the grid as back-up and to keep the batteries topped-up.

2. I have ordered for eight Pylontech batteries (US3000). Following the advice of @DayAndNight and because the long (2 metres) Pylontech cables carry a maximum of 120 amps, I have decided to keep the batteries separated in two groups of four. I couldn't find anyone to make cables that carry more current. Moreover, the Pylontech BMS most likely limits the current. I plan to buy eight more Pylontech batteries. The plan is also to put these in two groups of four, so that I have four groups of fours. No question here.

3. I know where to put fuses, but I'm confused as regards the volts! According to various Victron documents, one should get a fuse ideally equal to the system voltage (in my case 48 volts) or the nearest higher equivalent (in my case 58 volts) and the relevant current rating in amps. But according to various websites including Littelfuse, a fuse can only protect wiring or equipment at its stated volts and amps. One should therefore get a fuse at the rated amps and volts (expected volts, not merely system volts). In my case, just one MPTT can output 250 volts and each of my batteries can output 58 volts (remember I have 8 batteries, potentially 16), all obviously more than the 48-system voltage. Most of the fuses go to 150 volts. There are fuses rated to 600 dc volts, but they cost more than 100 US dollars. Moreover, there are specifically-rated photovoltaic fuses which cost even more. What should I get?

4. The same question applies to busbars. Most busbars are not rated, some have amps but no volts (like Victron's) and the rated ones, at least in the US, go only to 150 volts (Blue Sea). I can get a busbar of 1000 amps quite easily, but low voltage. What should I get? I will be dealing with about 1000 DC amps and 1000 DC volts in the busbars as distribution points.

5. The Lynx Ion manual says you can get two Lynx Distributors only but it is quiet about the Power-in. Can you get two Power-ins (without the Lynx Ion shunt and without the Lynx Distributor) and use them as fused "distributors" instead? Do the Lynx Power-in and Distributor really have two busbars each? From the images, I see one "red" fused busbar (positive) and a would-be black (negative) busbar eaten up by space for wires and fuses for the positive line.

6. In terms of communication, the plan is the two MPPTs and the two Quattros to talk to each other and to the Pylontech BMS through the CCGX. The Victron schematic suggests this is possible though some of the manuals say otherwise. Is this possible? (I guess "yes"). Should I wire my loads to the first or second or both Quattros? It doesn't matter to me how they are wired provided they can monitored through one CCGX.

Thanks. Sorry for the many qurstions.

Fideri