Hello Community!

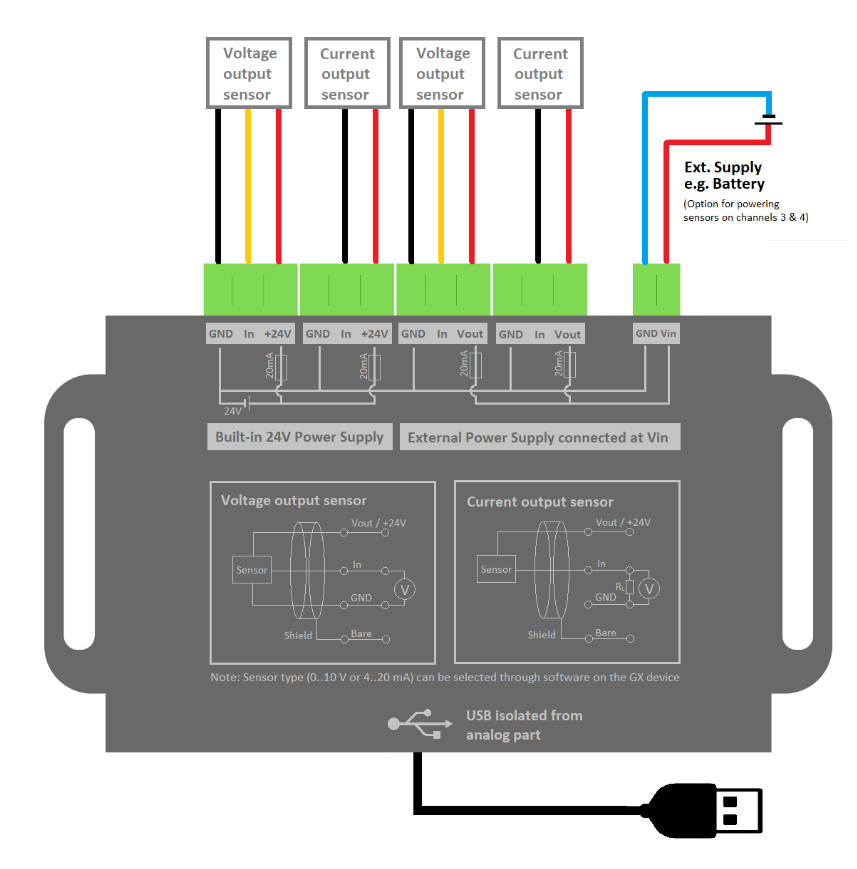

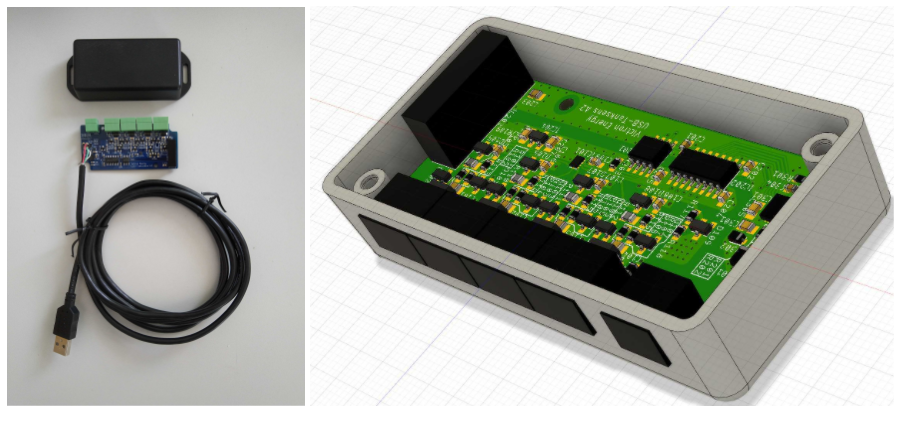

We’re considering to add a USB accessory to our GX product range, to add 0 to 10V, as well 4 to 20mA inputs.

But since all of us have very limited experience with 4 to 20mA tank senders, we're looking for some input:

- Is it always 4mA = tank empty, and 20mA is tank is full? Or do the empty and full levels need to be configurable in a software setting on the GX Device?

- And how important is it that the transducer can be powered by our device?

- Anything else we should keep in mind when designing a 4 to 20mA input? Good features you have seen else where?

Also, if you are using 4 to 20 mA senders, please post a link to a datasheet or specs below. And if you have an opinion on the sender, what you like/don't like, welcome to add that.

Lastly, most questions above are for 4 to 20mA, not for 0 to 10V - but if you have special comments about 0 to 10V, welcome as well - obviously. The product we have in mind will have inputs that can be used for both types.

Note, that this is quite early in the product development, I can’t say anything for now with regards to availability dates.

All the best and thank you! Matthijs

ps. just to prevent any question about this: we'll soon launch a new Venus OS version that can work with irregular tank shapes, as well as naming tanks and some more features: all those features will also available for the 0 to 10V and 4 to 20mA inputs. Details here.