I have a SmartSolar MPPT 100/50 with SmartBattery Sense (SBS) running with 1.42 firmware. I've been suspicious that the MPPT would sometimes not use the SBS voltage as a result of seeing impossible battery max and min voltages.

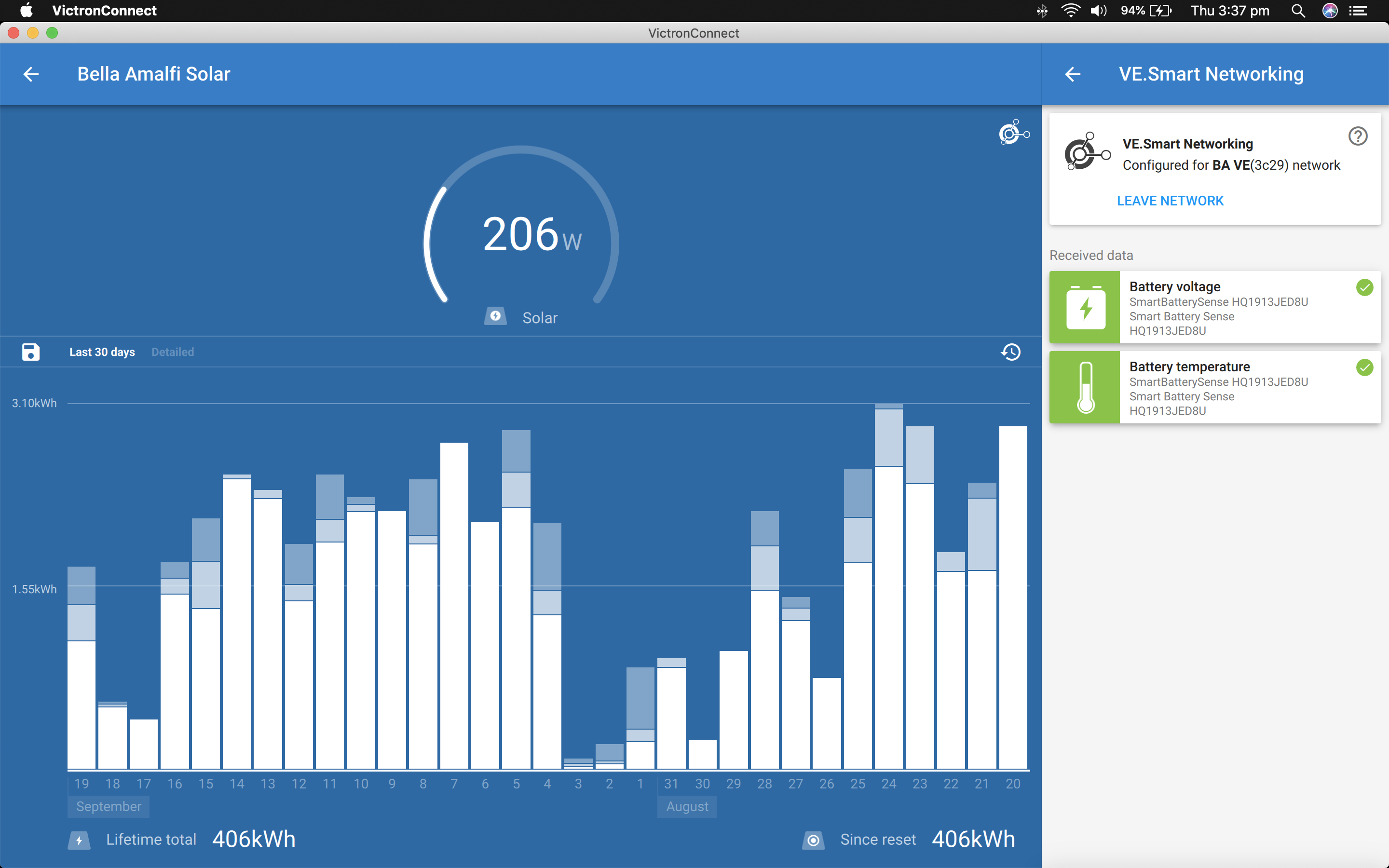

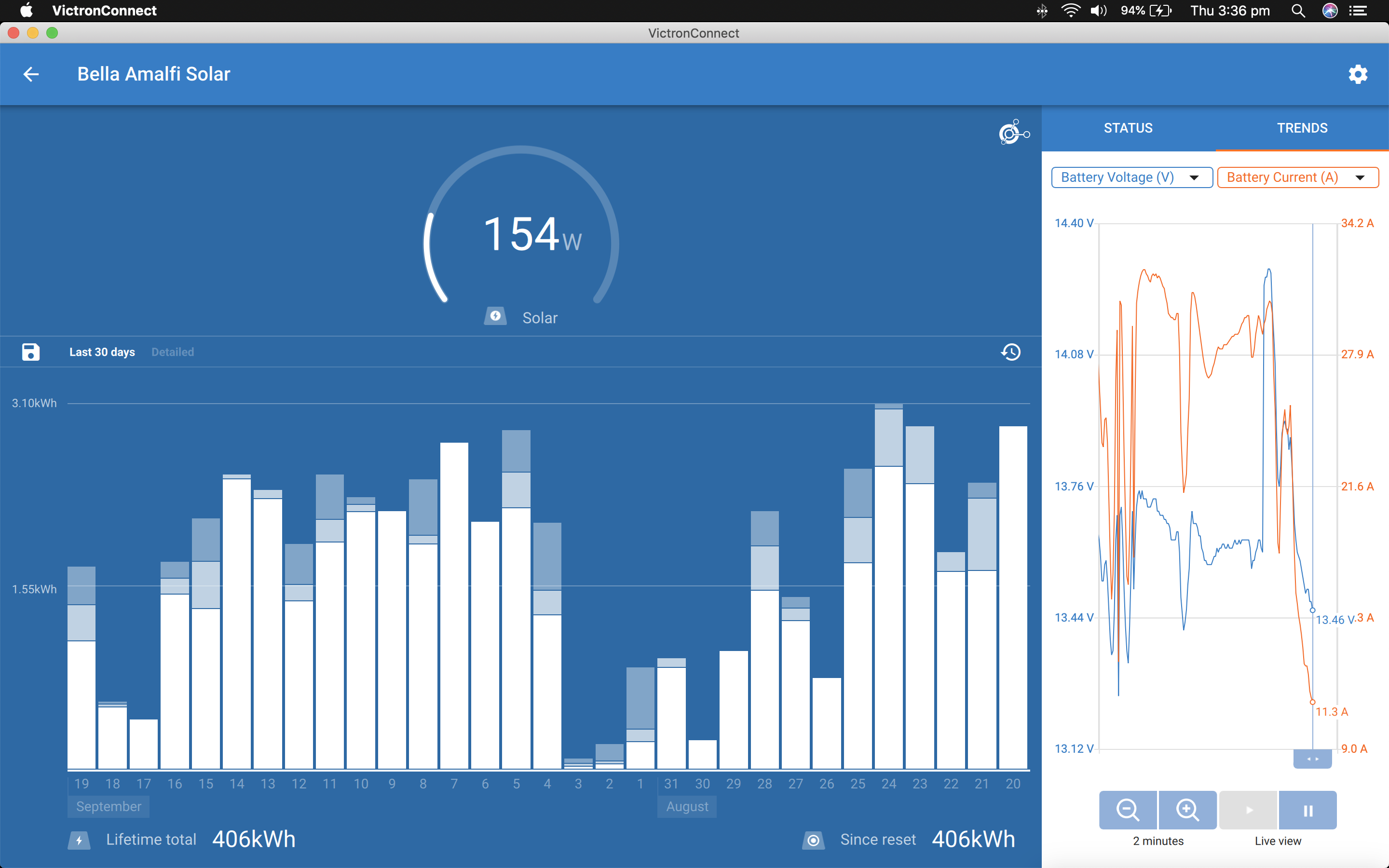

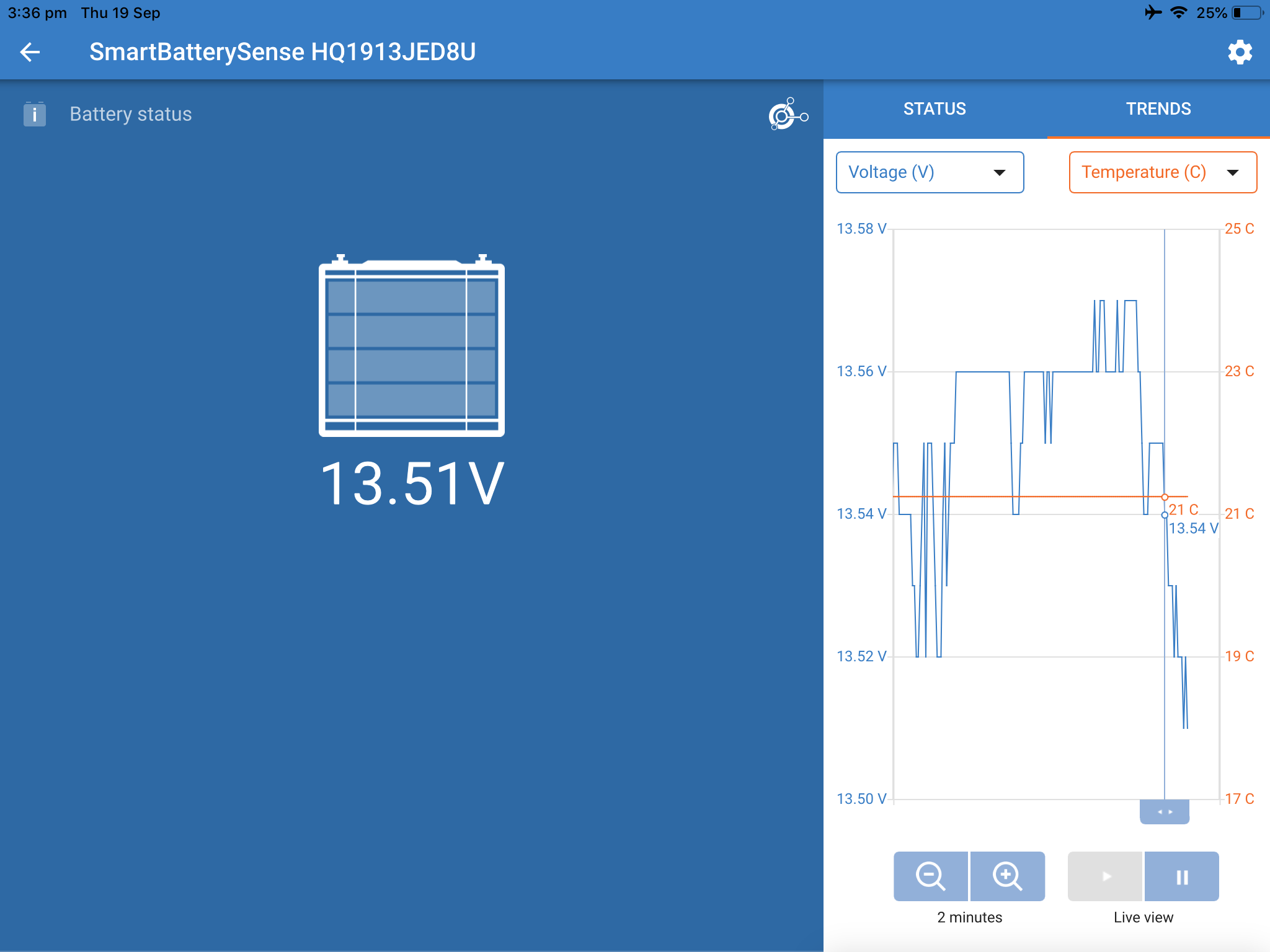

Today I was able to prove this as the system is locked in this problem state. Attached are three VictronConnect (VC) screen shots as follows:

- MPPT VE Network confirming its connected to SBS and receiving voltage and temperature data.

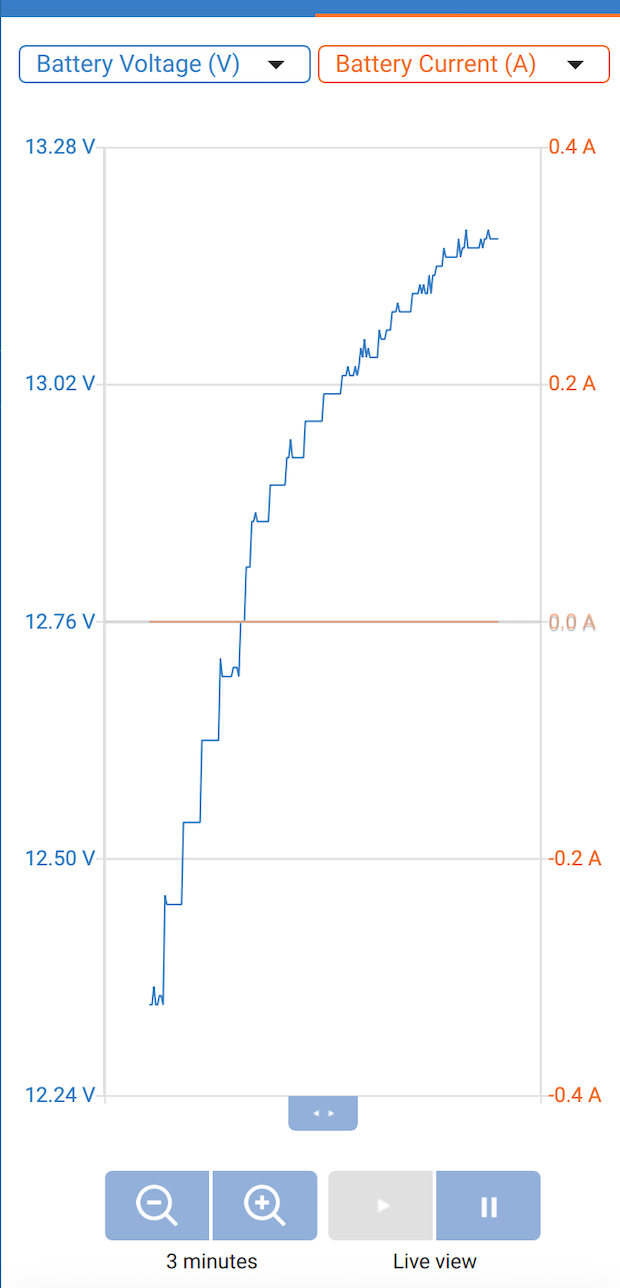

- MPPT battery voltage trend graph over 2 minutes.

- SBS battery voltage trend graph over exactly the same time.

This has captured the moment when the MPPT is saying its using SBS voltage data but in fact is not.

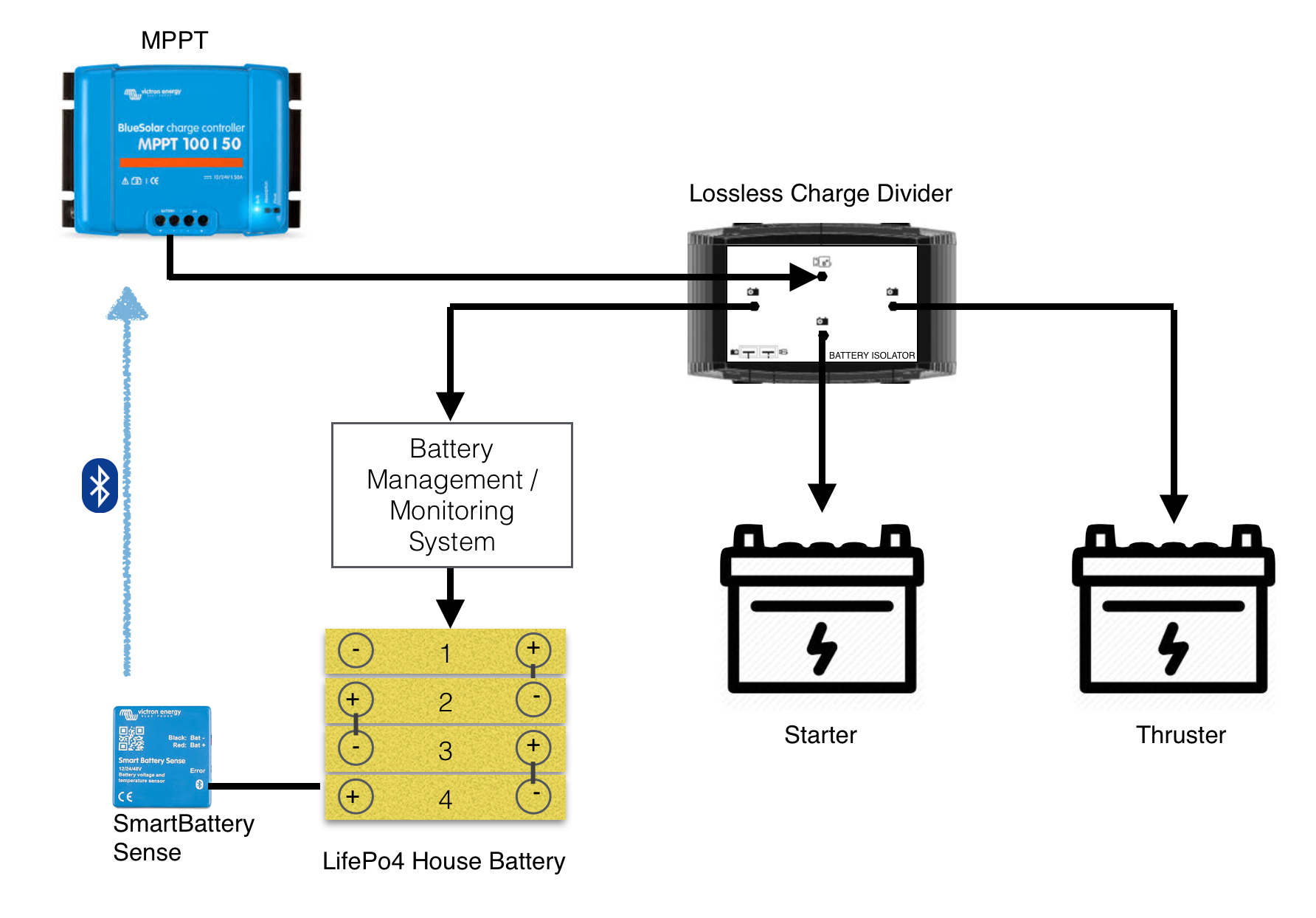

The following notes as some background:

- The SBS is mounted directly on the battery terminals and within 500mm of the MPPT.

- The MPPT passes through various BMS components (eg Fuse, Switch, Shunts) and hence has some resistance (Thus the need for the SBS).

- All connections are tight

- I have performed a power cycle of the SBS

- I have disconnected and reconnected the MPPT from the VE Network

- I have software disabled and re-enabled the MPPT

- I have NOT performed a power cycle of the MPPT but will try this tonight after the sun goes down

- At this stage the system remains locked in this state.

I believe there should be no way this could happen as a result of installation and is potentially a major software bug.

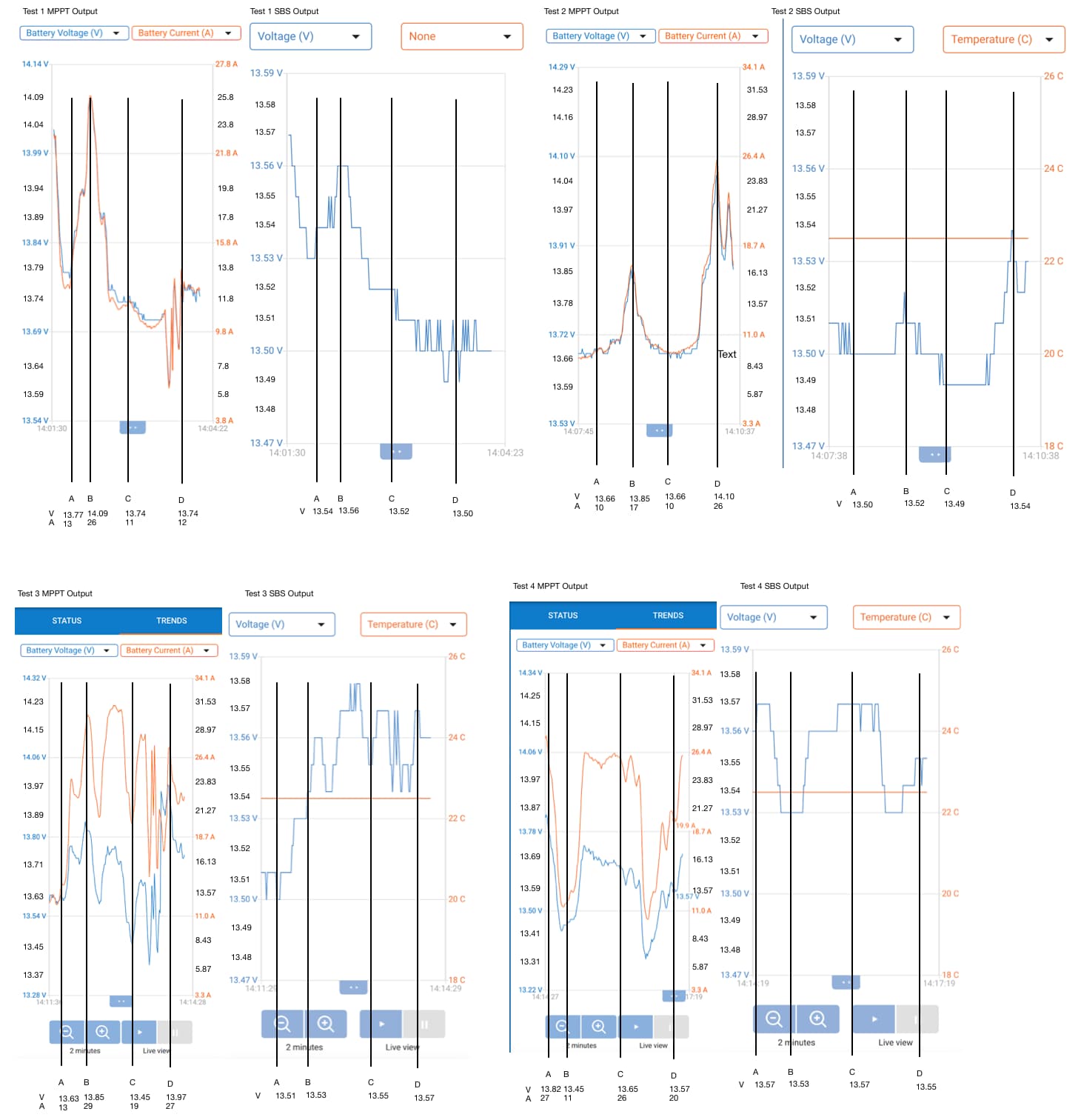

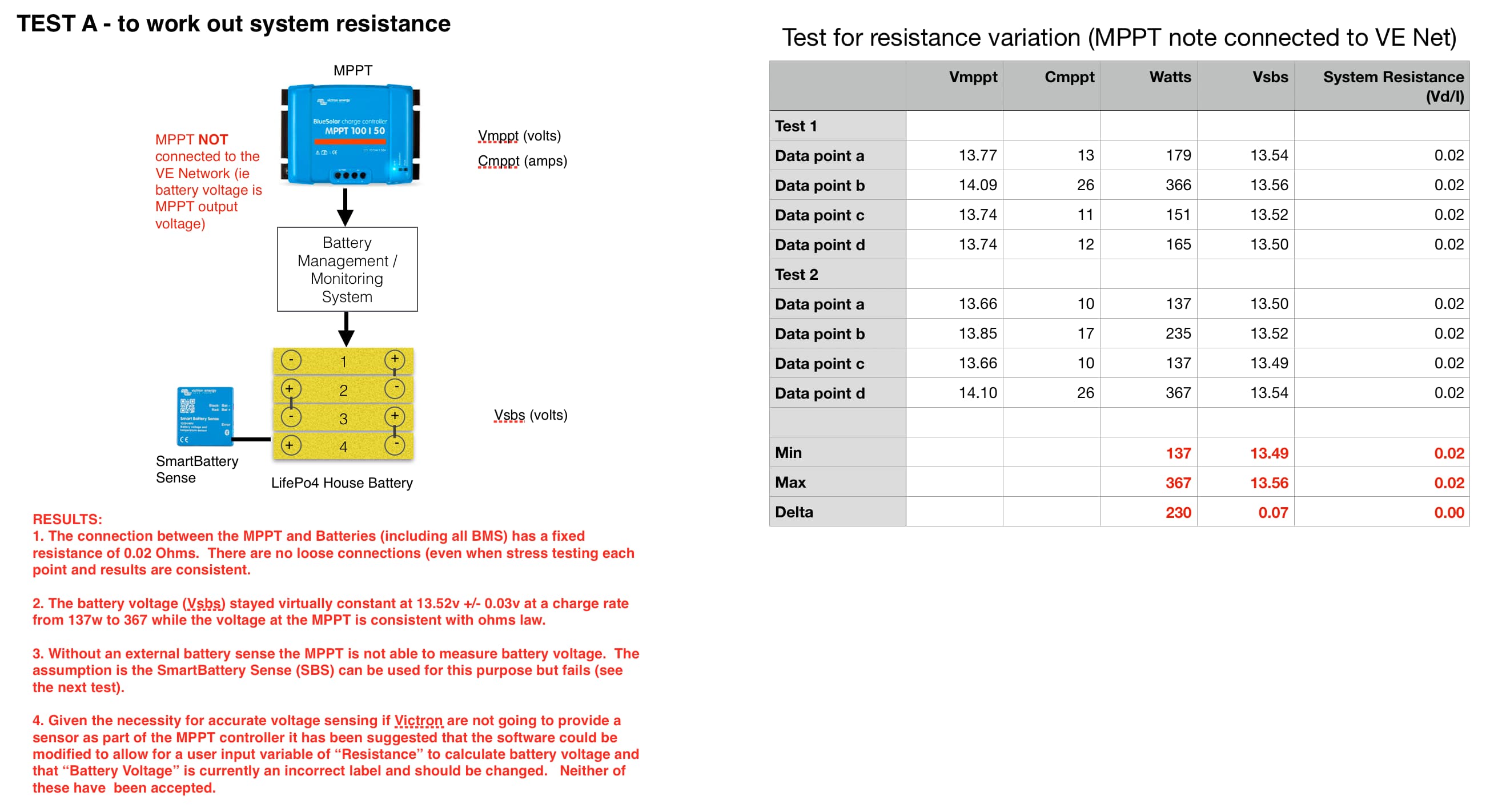

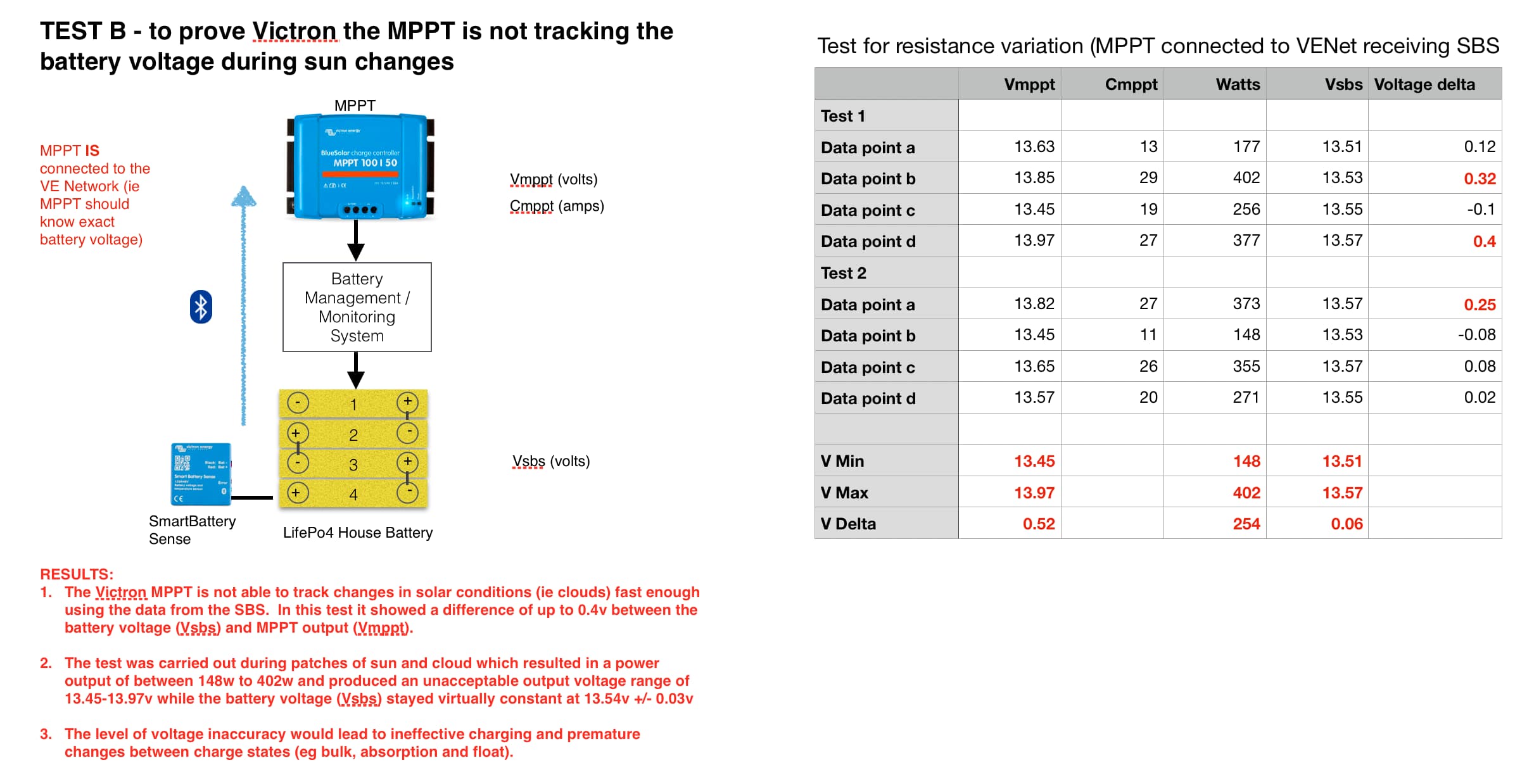

7. The datapoint summaries in the above two images were collected from the raw test graphs that are provided in the following for reference only. The top row is the first test and the bottom row the second. Each row contains two separate runs and output from the MPPT and SBS over the same period. Four data points were collected from each run totalling 16 data points for Voltage at the MPPT (Vmppt), Current ouput (Cmmpt) and voltage at the battery (Vsbs). Many other tests were run that were consistent with the results of these.

7. The datapoint summaries in the above two images were collected from the raw test graphs that are provided in the following for reference only. The top row is the first test and the bottom row the second. Each row contains two separate runs and output from the MPPT and SBS over the same period. Four data points were collected from each run totalling 16 data points for Voltage at the MPPT (Vmppt), Current ouput (Cmmpt) and voltage at the battery (Vsbs). Many other tests were run that were consistent with the results of these.