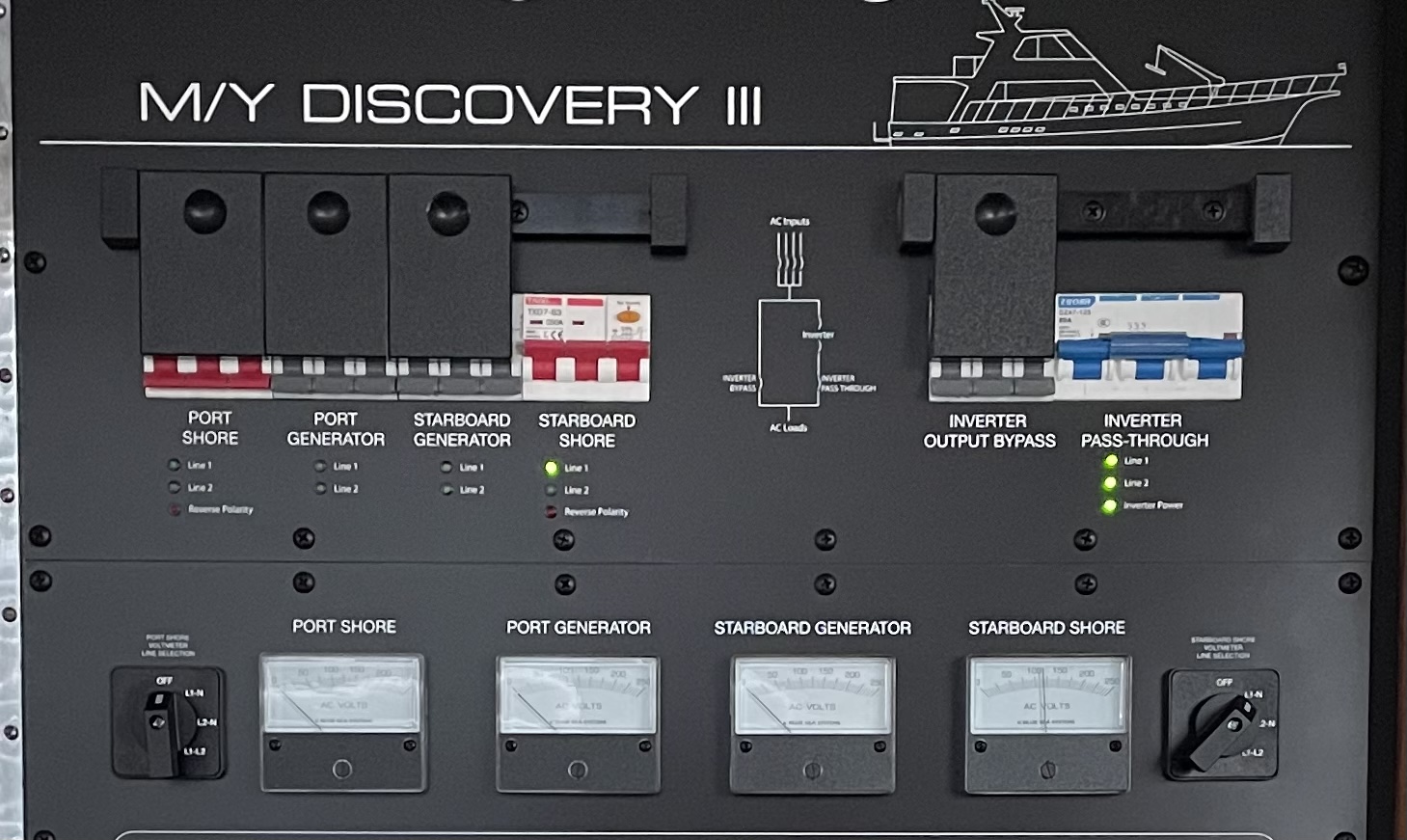

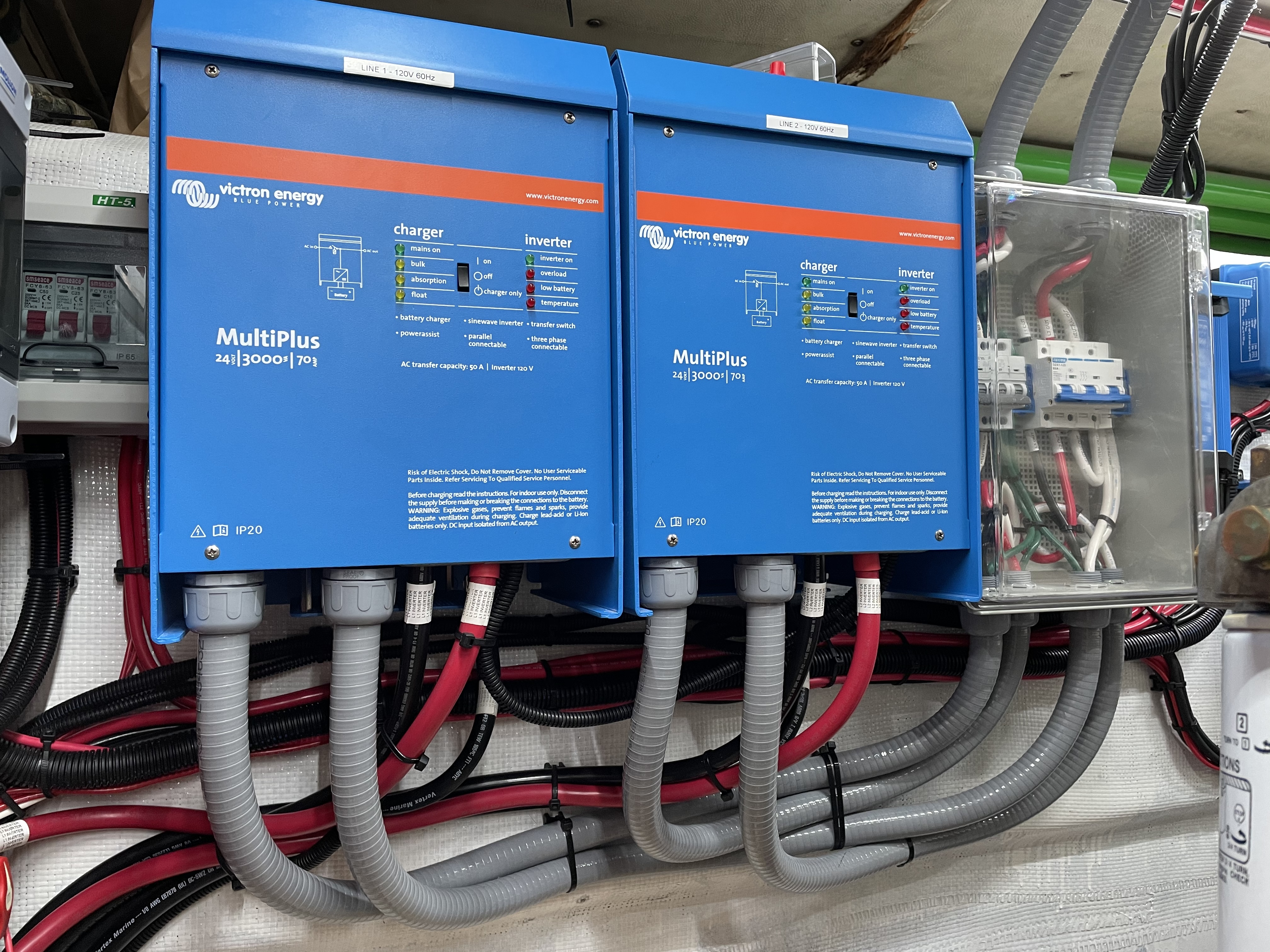

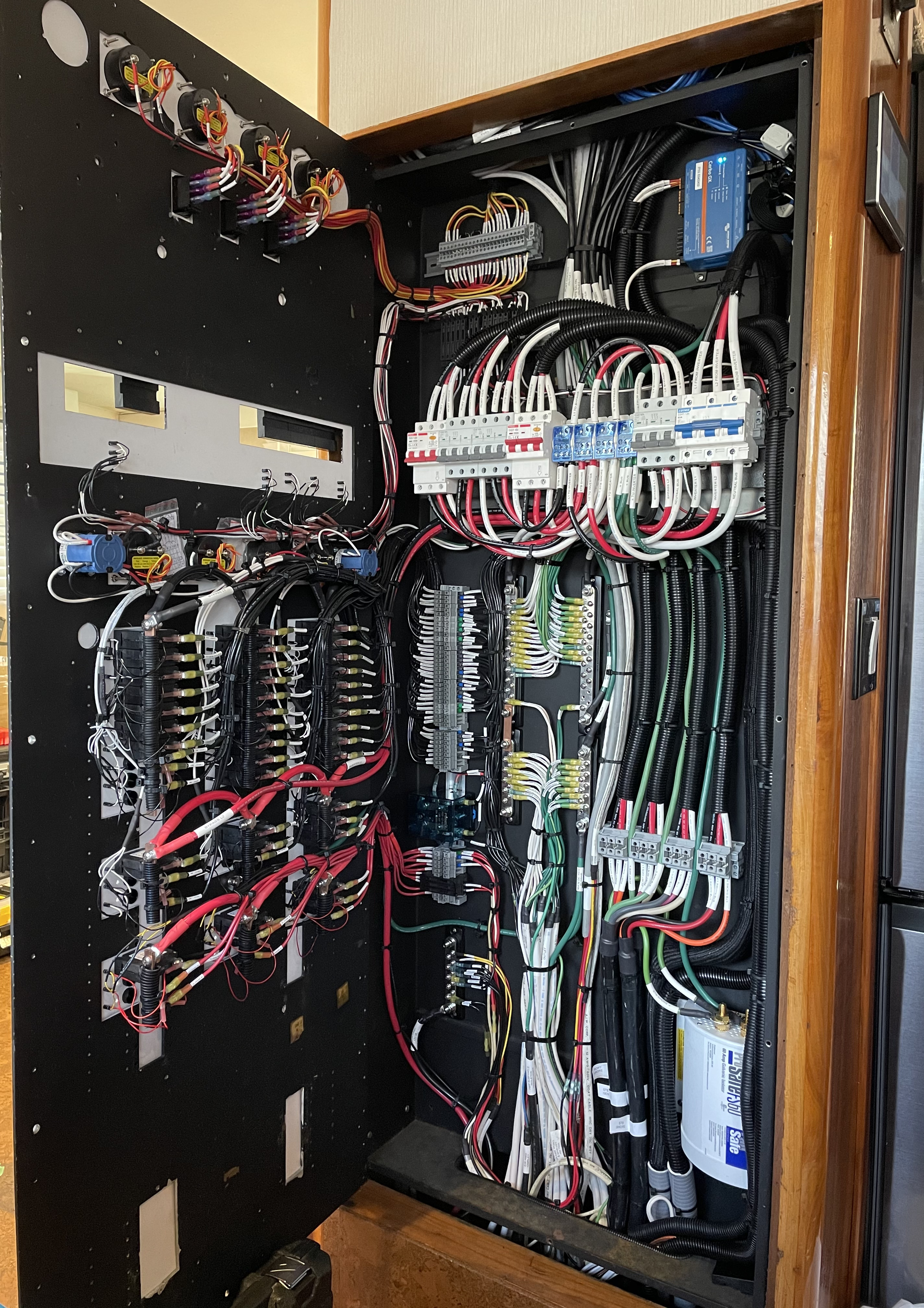

I'm planning the install of a MultiPlus II 2x120 inverter/charger into my boat. My shore connection is 120/240 50A and also have an onboard 12KW generator that is also 120/240 50A. The only loads on the boat that are 240V are the three air conditioning units. These 240V loads are fed from their own secondary shore/generator/off selector switch. I have been following the Victron install schematic as it is the closest to my application.

I have a few questions/clarifications regarding this install...

1) The Victron schematic above shows that AC Out1 is/can provide No Break loads for 240V out which MultiPlus II manual says that is not possible? Can anyone explain the contradiction here? Is the schematic incorrect?

2) My plan was to only use the MultiPlus to power the 120V loads fed from the first shore/generator/off selector switch. I was going to run the output of that first selector switch to a new 3 pole 50A breaker then to the AC Input on the Mulitplus II and then AC Output 1 back to the panel to the 120V side master breaker. Does anyone see a problem with this plan?

3) I was planning to leave the second shore/generator/off selector providing the 204V as is without running any of it through the inverter. Am I missing something here? Does/should this run through that selector switch to AC Out 2 back to the 240V loads? Seems unecessary to me.

4) The single input/dual output cutoff/battery switch from the Lynx Distributor running to the inverter on the positive...does anyone have a part number/source for that switch they are using? I have found single input/output and dual input/output switches but not the combo.

Thanks and looking forward to the replies.