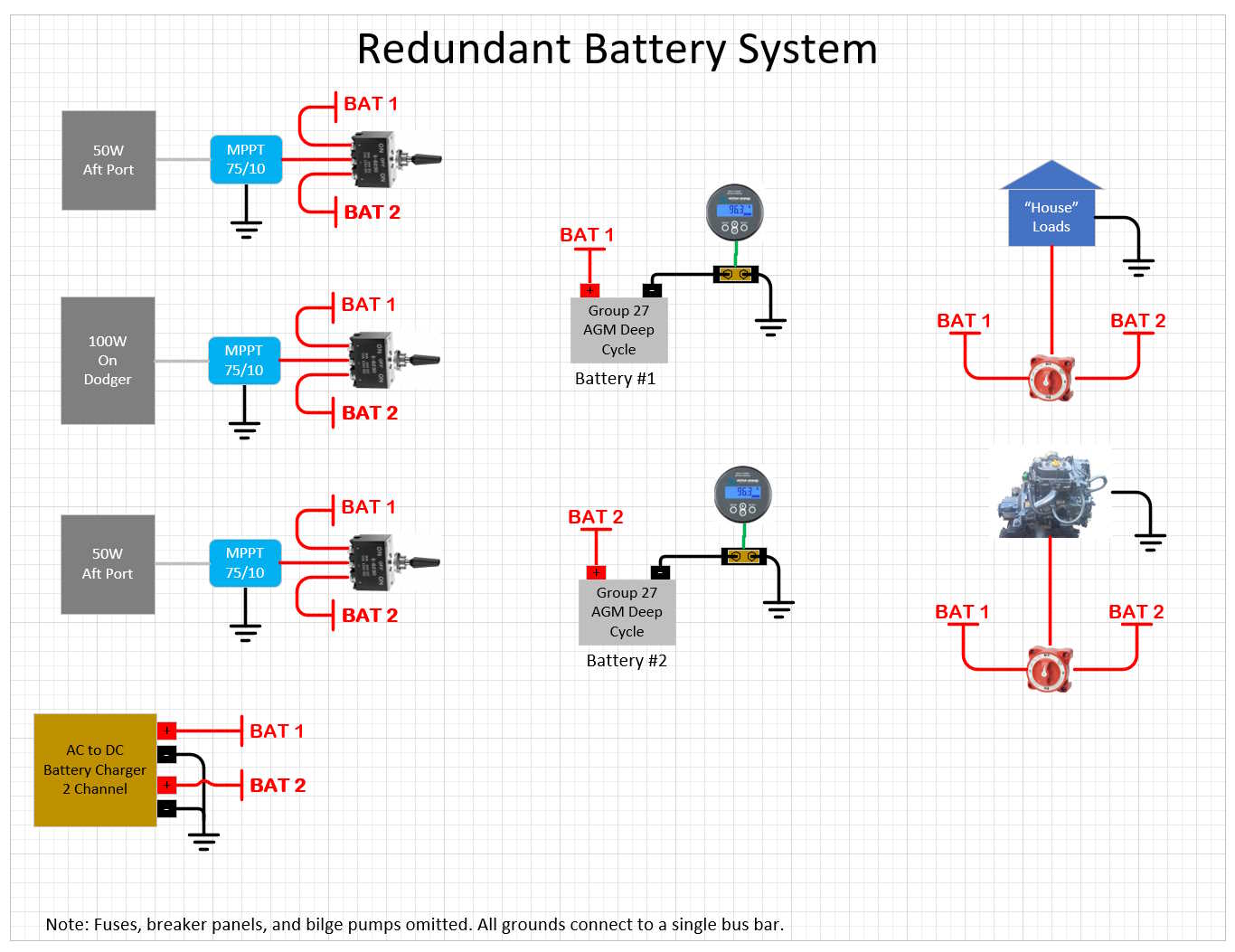

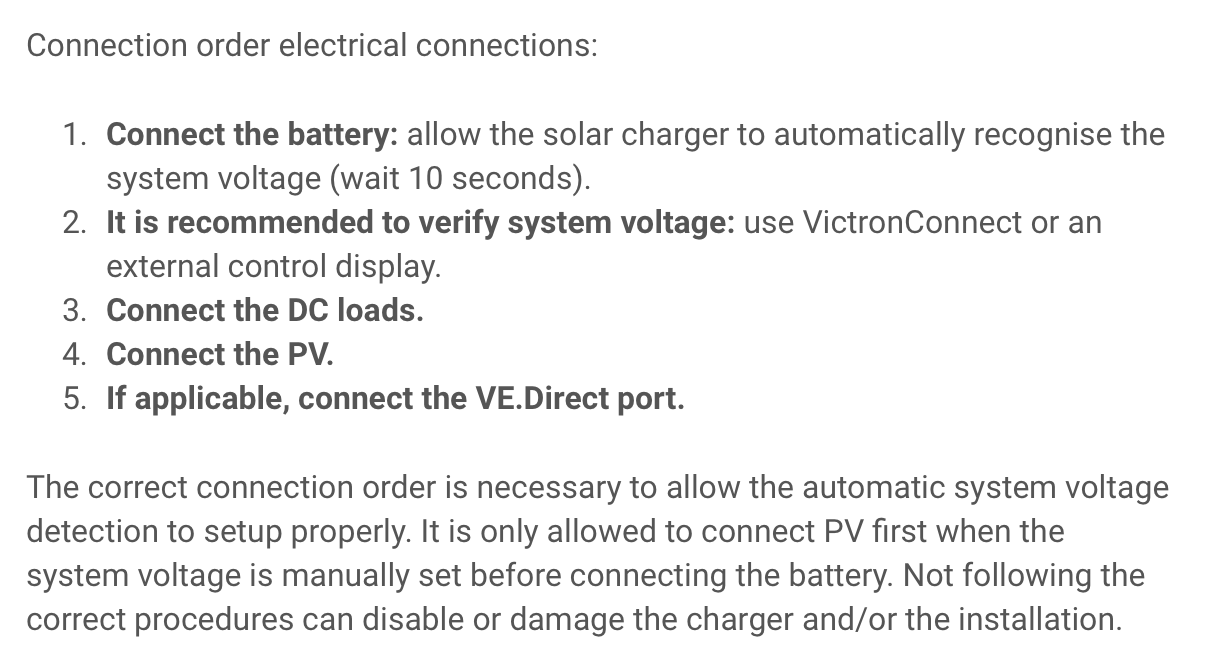

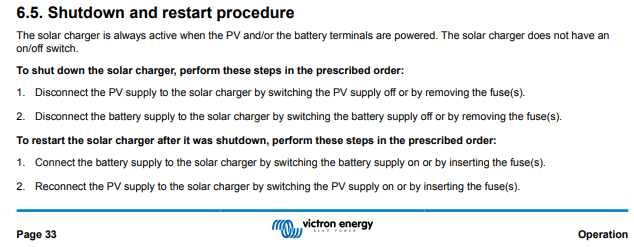

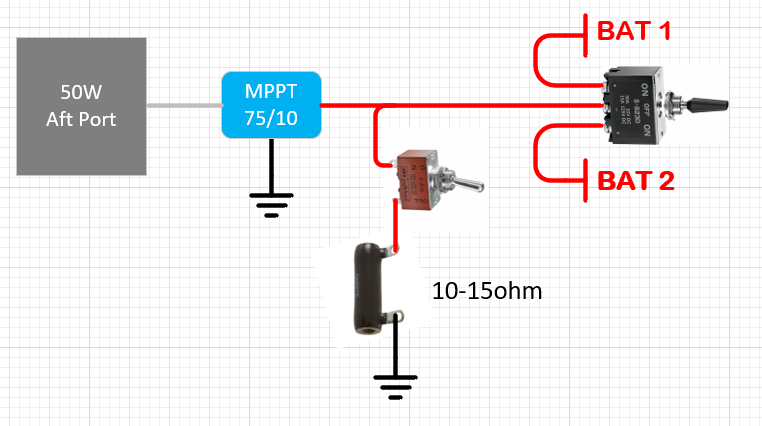

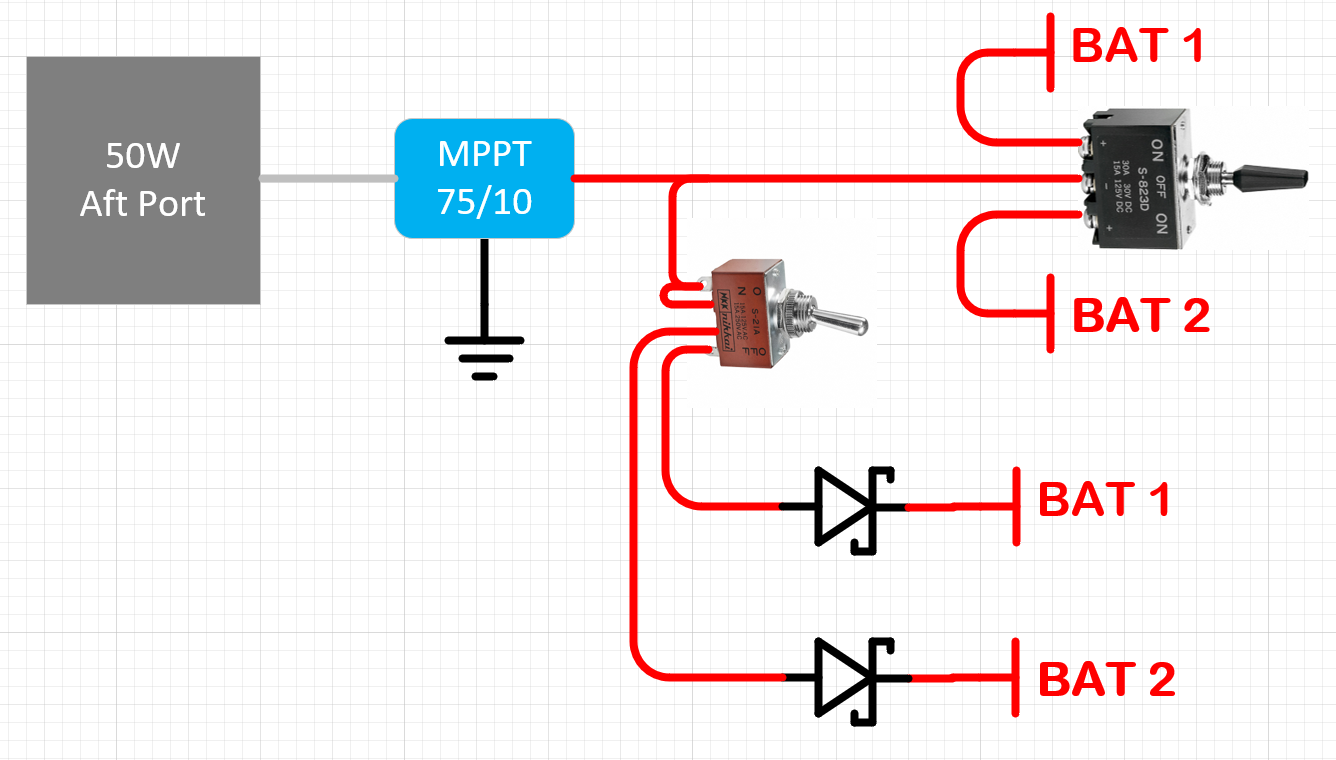

I'm in the process of setting up the system shown below. It's for a 30' sailboat. I expect significant shading so each panel gets its own mppt charger. The system is fully redundant when underway or at anchor. Can the controllers handle being hot swapped between batteries as shown. Or, do I need to add a switch between each panel an controller so I can disconnect the panel before switching the controller to the other battery?

Regards,

Greg