I solved the SOC issue. I don't use it anymore!

Take the SOC value to an indication of charge, not an important value. we have some other indicators more reliable that the batterie is weak.

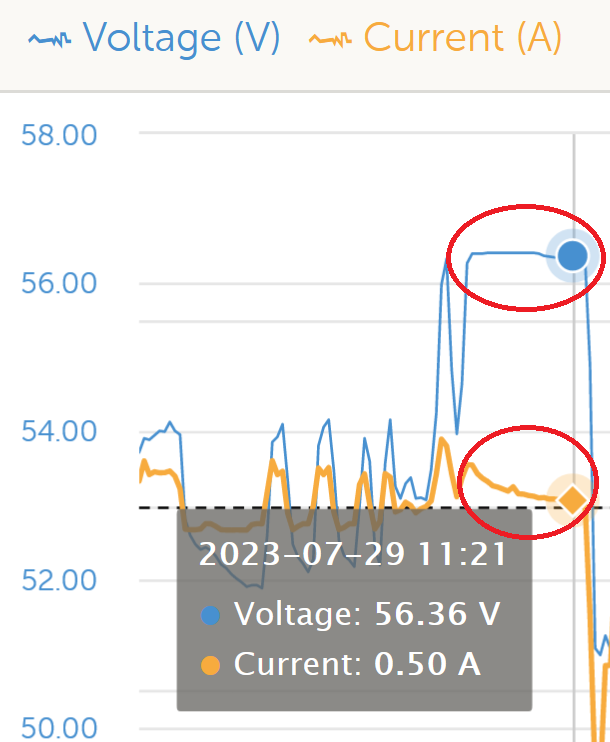

I verify my batteries only in VRM with the current and voltage during the charging absorption phase.

I use lead batterie but this verification is good for other batteries, and to know if my battery is full I look the TRUE tail current has gone low enough when it is with the absorption voltage.

When I see those curves batterie in voltage and current I am very Happy. The voltage can change with temperature. In this case the temperature is 18°C. On this figure we can see the effect of the cloud just after the begining of the absorption phase and a potential false resynchronisation @ 100%.

Synchronization in Victron apparatus is not reliable when charging with pure solar. The transition Absorption to Float is not realiable because the curent and the voltage are not monitored in the same time at the absorption voltage value and the tail current. The Victron définition that I see on my product is: if the voltage had cross the absorption voltage and if the current is drop under the tail current, then the end of absortion is done. IT IS A FALSE DEFINITION.

Both must be true at the same time. This wrong definition is implicit because the battery current is not known by MPPT and VENUS. This is a serious hole in the system. This limitation is not explained any where in documentation.

From what I have observed if the voltage drops because of a cloud, then the voltage drops and the current drops, which is normal, but that the absortion-> float transition is done, it is not at all a normal definition of the full battery charge. So the synchronization is not reliable.

This fundamental problem can simply be solved by doubling voltage and SOC monitoring by the ASSISTANT in the Victron apparatus. If you want I can share my assistant.

What is well done in nature is that batteries have a voltage that decreases faster if you draw a lot of current (Peuckert). It is physical since the chemical reactions are done on the surface first and then the energy is pumped deeper and deeper into the matter of the electrodes. We can use this effect to control if the batterie must be charge.

Just characterize your battery and know what is the voltage from which it is wise to charge or at what voltage you decide to charge (we don't have to know this peuckert coefficient). It is the rebulk voltage that is important therefore. And it is you who decide this limit voltage since it is programmable in the MPPT. It is one solution. I don't like this solution, because the MPPT in winter doesn't reliable without sunshine. I don't like living on credit on the battery account.

I have a prefered solution in winter.

IN OFF GRID, If on the contrary you want to use the grid or a generator instead change your battery prematurely, then you can switch the priority "grid to main loads" and charge the batteries by the MPPT, this is another better solution. In this case, I programmed a very low rebulk voltage (0.1V). and switched the mains relay to "not ignored" to assist the inverter with the MPPT when the voltage is too low. If no sunchine you can decide to put the batterie in storage mode and use the grid or generator.

To make this solution:

For resynchronisation I use only the float voltage from Easy Solar charger. His value is set with a voltage just under the value of the MPPT (IE: 54V for MPPT and 53.4V for internal charger (like a storage value)).

And when the batterie voltage is crossing this 53.4V; the SOC is reset to the good value of AH. (you must characterize the capacity of batterie for this voltage).

Then the resynchronisation is done at 85% for exemple (or other value) of the batteries. This voltage is very reliable and only this voltage.

To cancel the false 100% resynchronisation I put the voltage of internal charger just above the absorption voltage of the lead batterie programmed in the MPPT. (IE. 56V for absorption voltage for the MPPT and 56.2V for the internal charger. For a lead batterie this value is the voltage of 2.34V per cell for normal potential of H2O electrolysis in H2SO4 solution, take care of the efficiency of your batterie, see the manufacturer specification for H2O electrolysis potential).

If I decide to reach 100% then I use the egalisation function of the MPPT smart solar to reach this value. In that case you can use egalisation as an additional absorption phase (it is benefic for all batterie to reach a higher compatible voltage). I put the value of egalisation voltage at 56.2V or 56.3V in the MPPT. In that case batteries are in a good condition without corrosion of electrodes during normal operation and the 100% resynchronisation will be good and set to 100% only for a few minutes each day if you want. For Lithium, the voltages can be adapted.

For lithium batteries it is also important do not exceed a maximum voltage. This maximum voltage corrodes the electrodes and the service life is decreased for all batteries.

Sorry for the long text an sorry for my bad english. I am a French man.

If you want my OFF GRID's assistant I can share this solution. It can be improved but it is a good basis. I did the entire program by the native assistants. and bypassed almost every problem I've encountered. 3 months of work and observation of Easysolar II GX 's behaviour.

Pierre