Hello community, i have a very interesting Question from my side because no one can answer me this. Also not my Victron parts seller.

- Standard ESS System with 3 or 6 Multiplus. 48-54V System!

- A Few Victron MPPTs

- Cerbo GX

- Shunt

Over the DVCC there is a current Limit for Battery. If the DC coupled feed-in is OFF, then everything is working fine and you can limit the current for the Battery with the DVCC Limits.

But if the DC coupled feed-in is ON, the cerbo-gx ignore the DVCC settings accordings victron manual and also tested in reality. The MPPTs need to be always on full power, to be able to feed in.

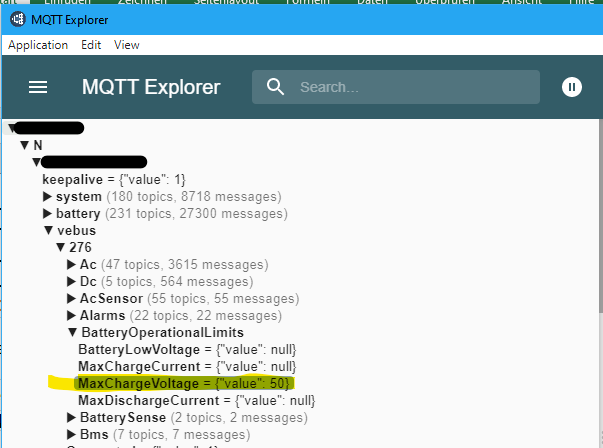

But how can i control now the Batterie current? Also the DVCC Voltage Limit doesn't work. This was my second idea, to adjust for example 45V Limit, then the Multiplus should move the MPPT Power into the grid, but it doesn't?!

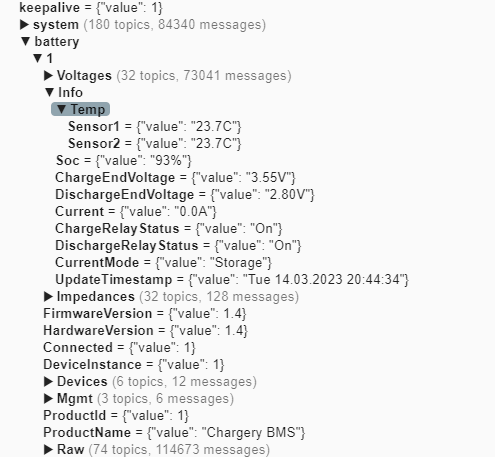

I want to prevent overcharging the Batteries, so activate some current or Voltage Limit, that the Batterie will not rise up more and more. Doesn't matter a few amperes in or out, but should be around +-5A. So the MPPT power should be used for the house + grid if the shunt shows 100% and then the multiplus should control the shunt current to 0A.

Is there any parameter to write in Node-Red to Limit the battery shunt current? Normally DVCC, but system doesn't listen to it with DC-coupled mode! Thank you a lot!