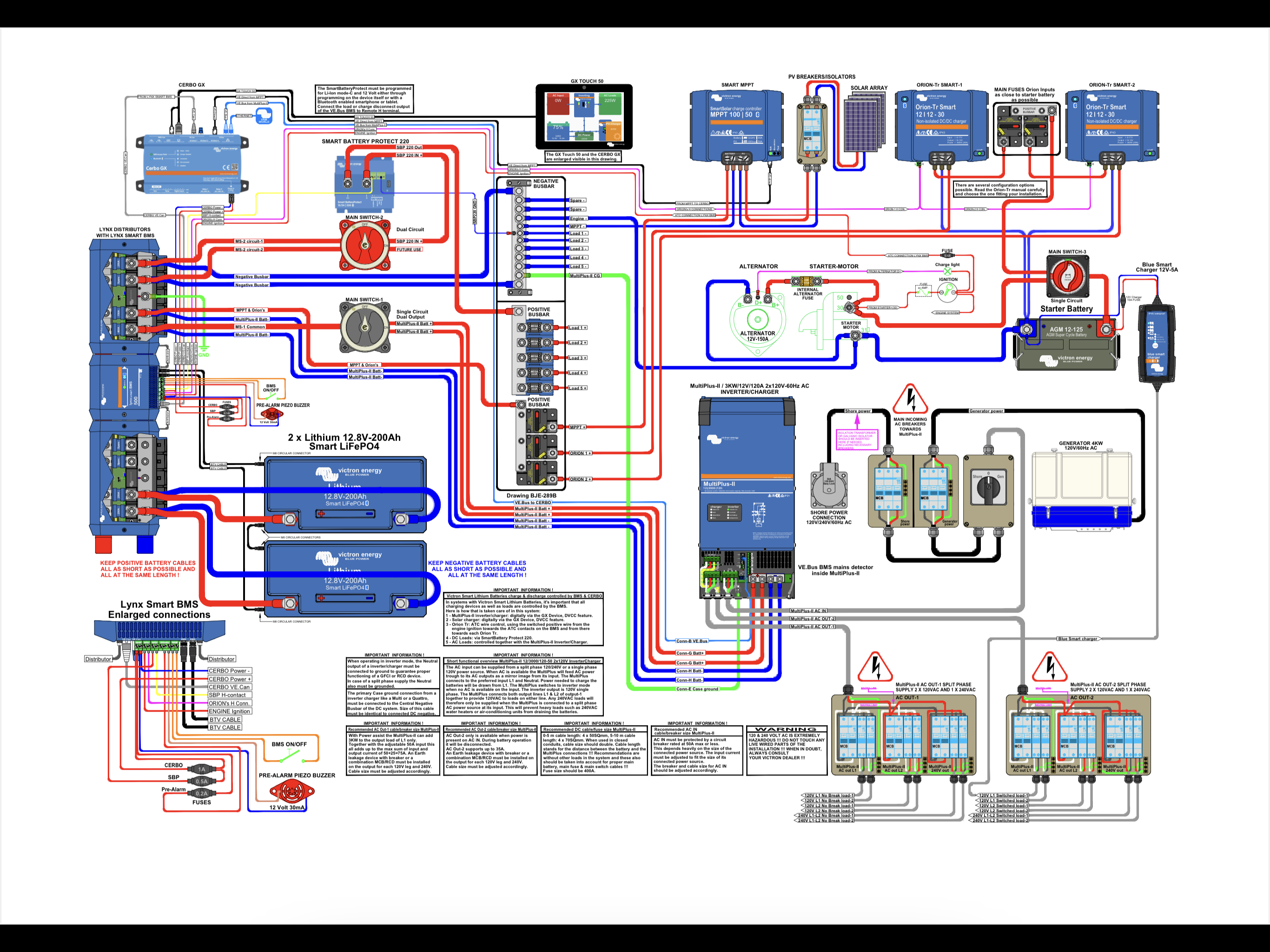

I notice in the various Victron produced circuit diagrams for the Lynx system, they never put a main system switch before the Lynx distribution system/Lynx Smart BMS, however most actual people building seem to fit a physical switch between the battery and the Lynx.

Is there a reason why I should fit a physical switch?

I’m assuming people don’t like relying on the software controlled contactor In the Lynx Smart BMS?

Is this just aversion to change, or is there a good reason such as a regulatory requirment?