Note: please see my latest update for additional information and findings.

---

Hi all,

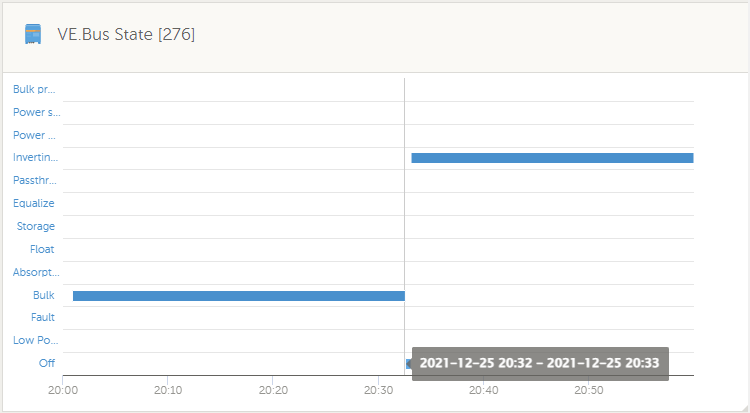

I've been having issues with my MP2 since installation. Every so often when the grid fails ("load shedding", substation trips, etc.) the MP2 shuts off for about a minute before starting up again).

System:

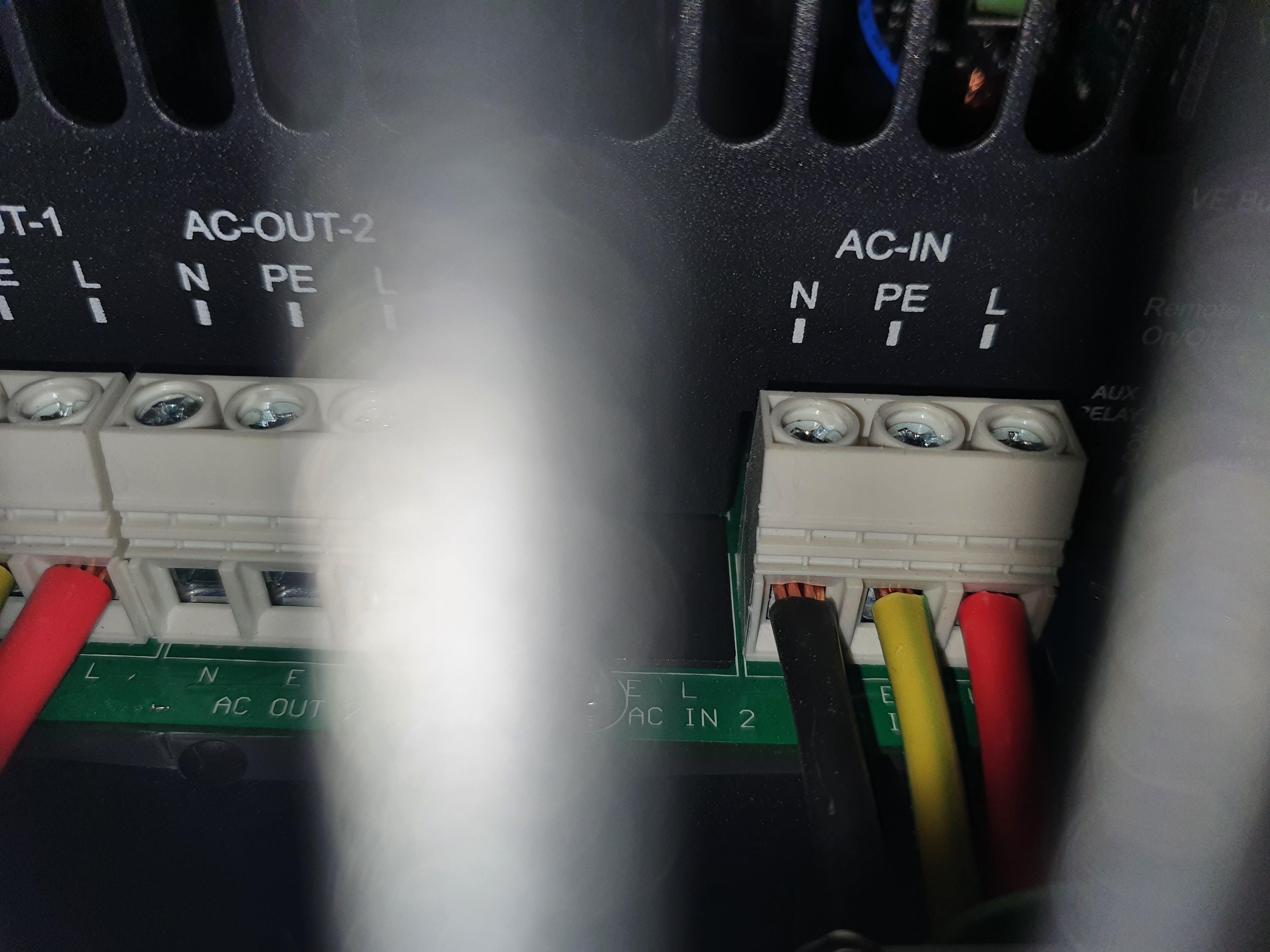

- 1 x MultiPlus-II48/5000/70-50 230V

- Firmware: v490

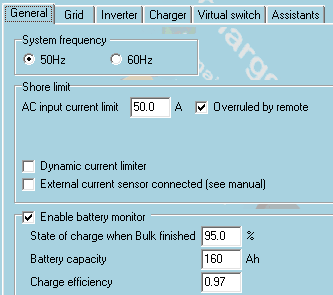

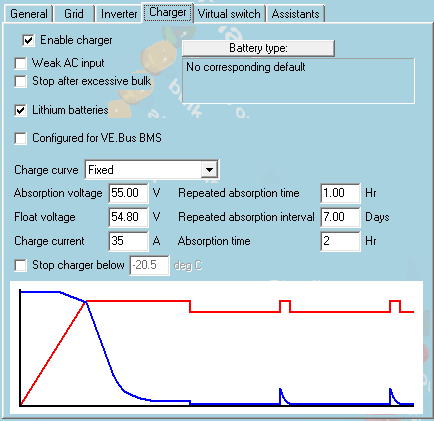

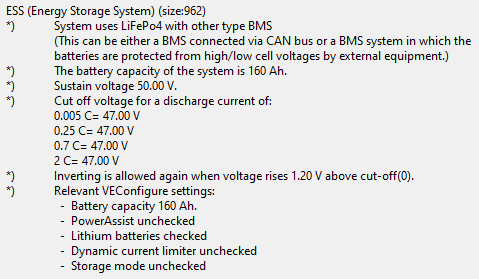

- 1x BSL Battery LiFePO48 Battery 8.2kWh (160Ah)

- 1 x SmartSolar MPPT 250/100-Tr VE.Can

- 12 x LONGi 450W mono panels

- Cerbo GX

- ET112 Energy Meter

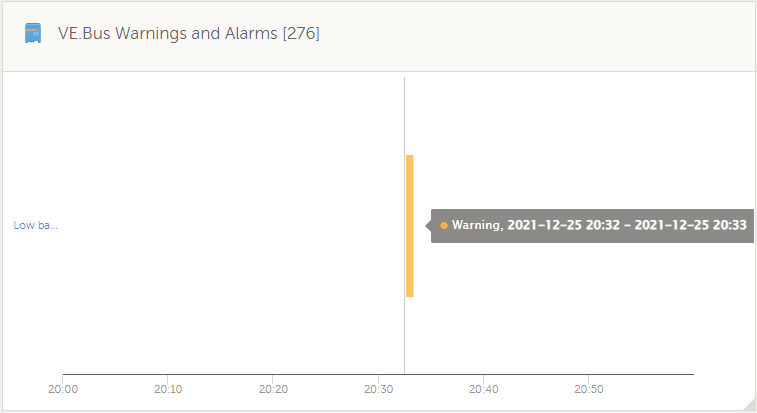

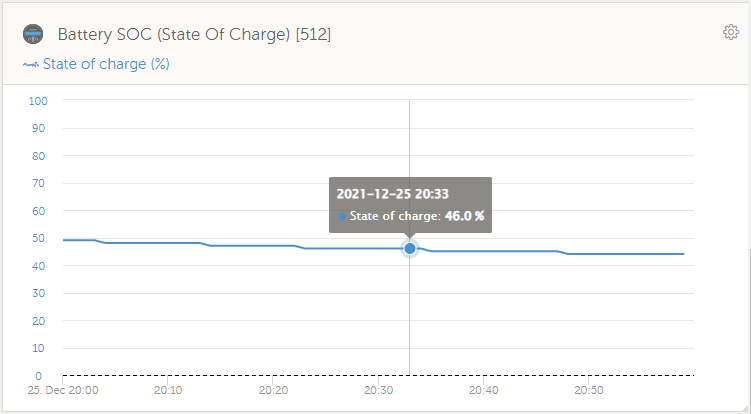

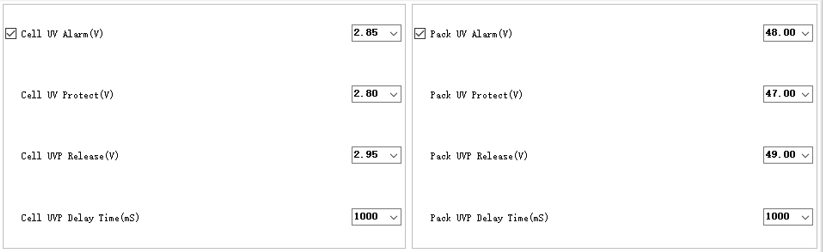

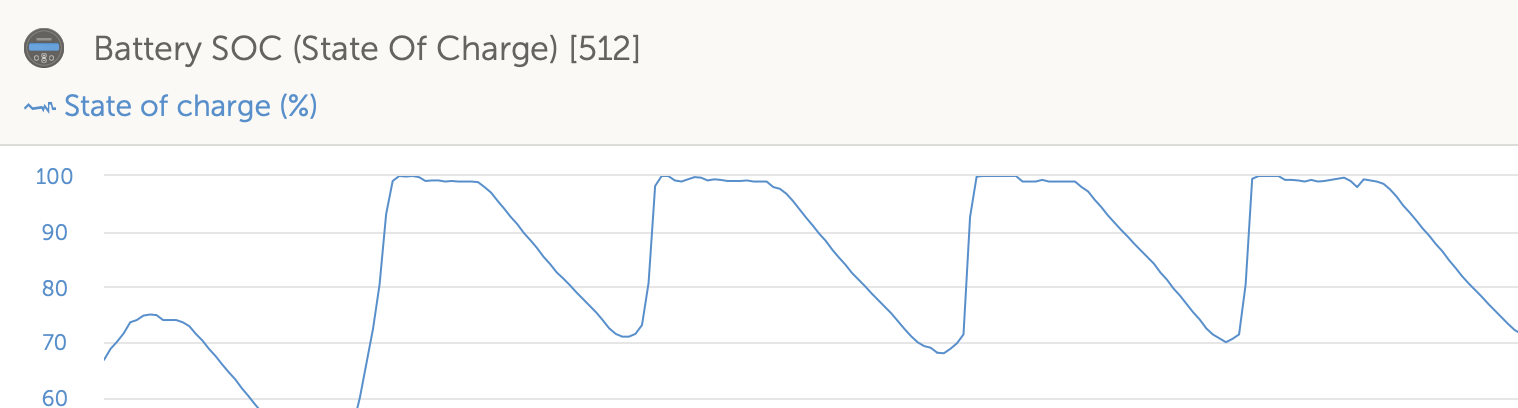

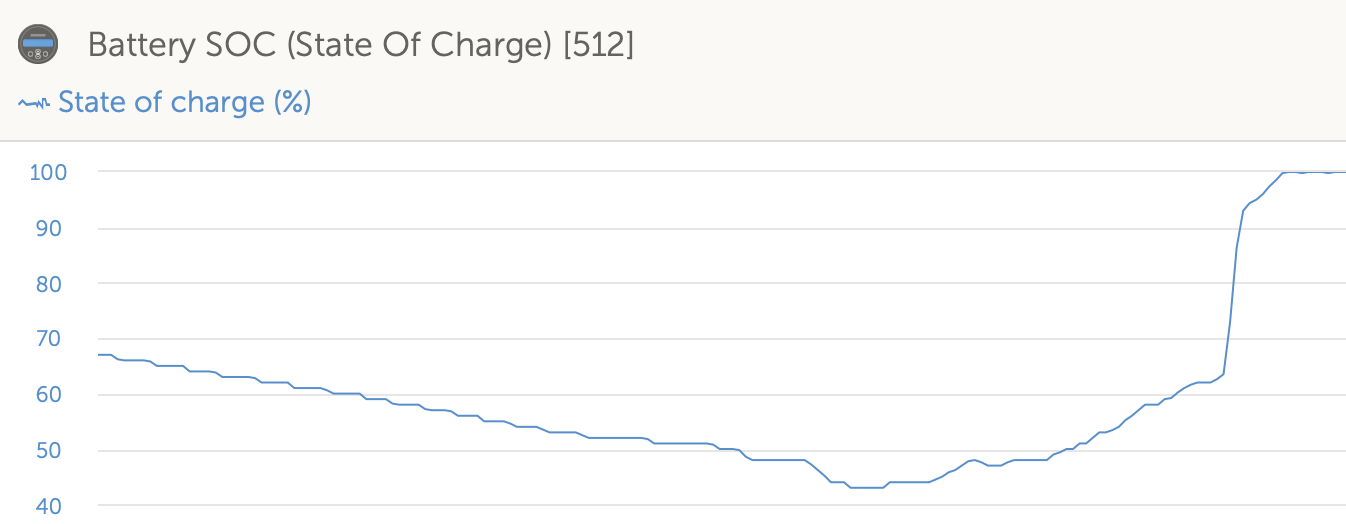

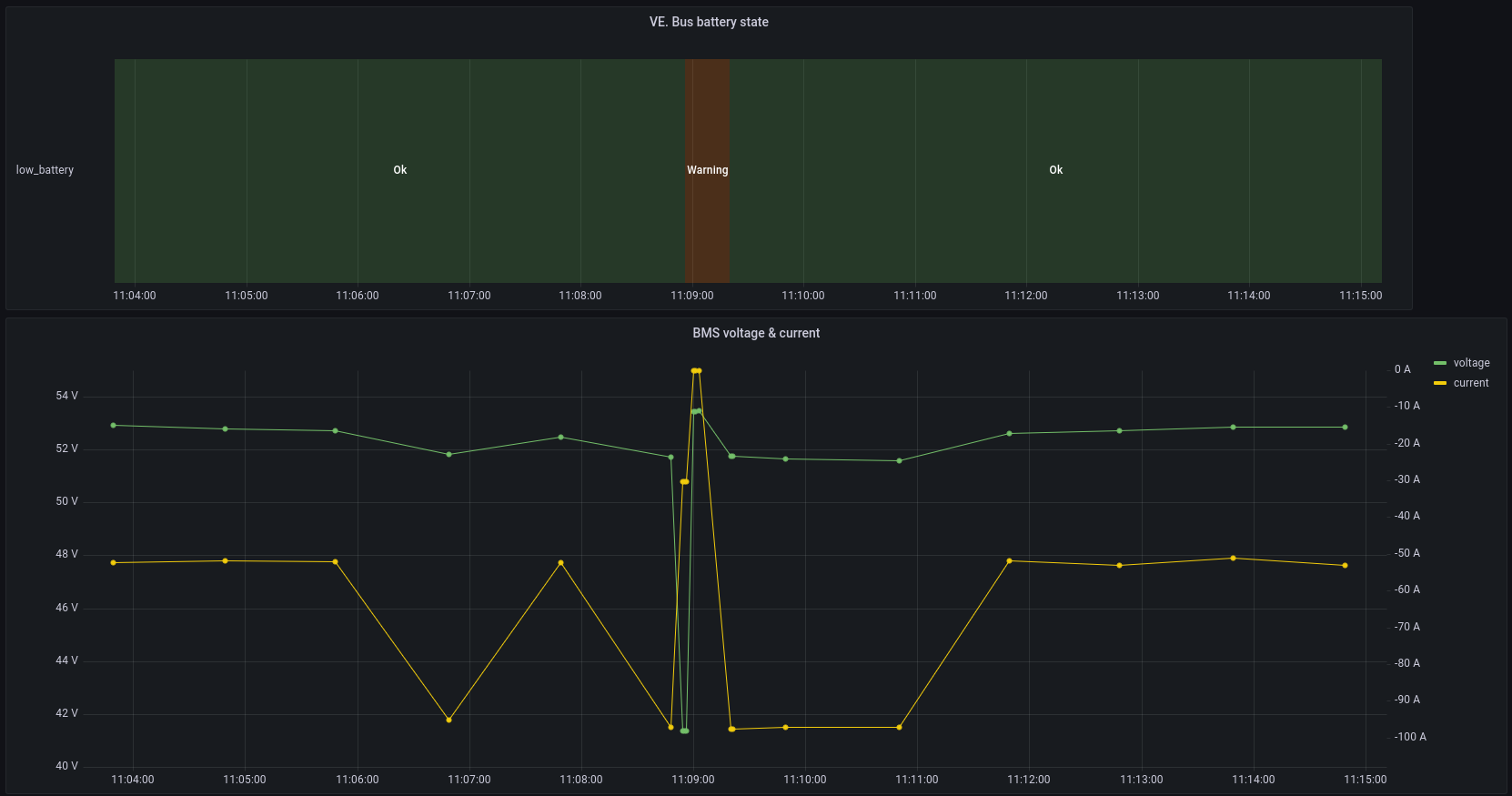

At first I suspected a battery (BMS or otherwise) issue, due to the fact that the shut off coincides with "Low battery voltage" warnings and alarms, as well as "High DC ripple" warnings. There's a whole thread about this. I however do not believe this is actually the issue, but rather just a symptom.

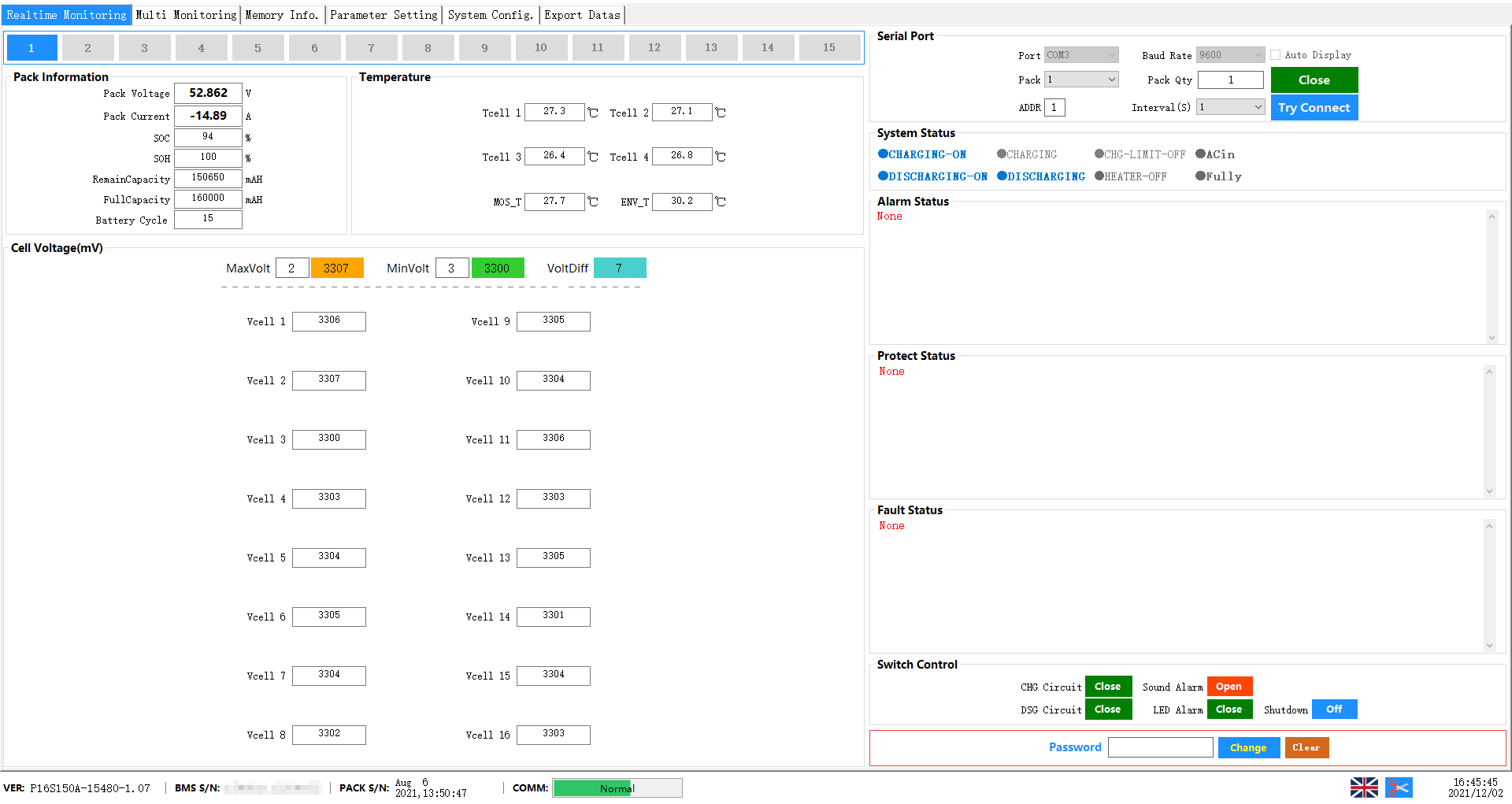

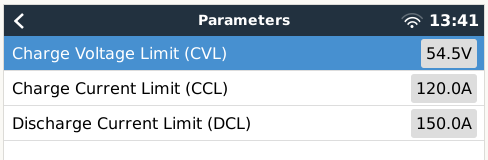

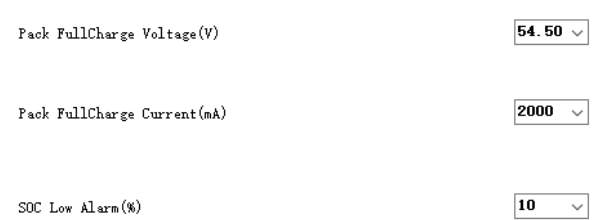

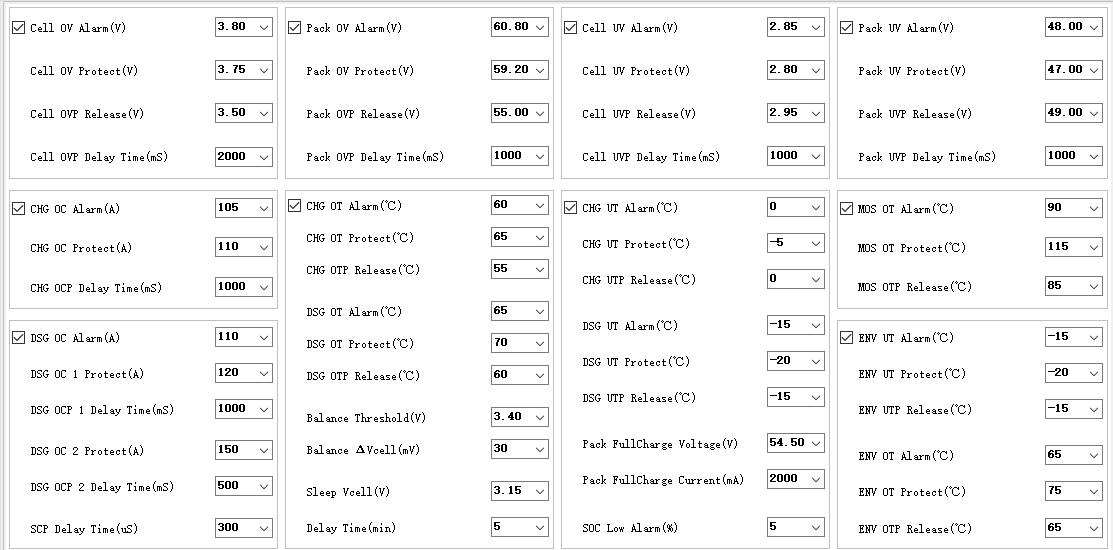

A battery supplier technician was on site a few weeks ago to inspect the battery, and reported that everything seems fine (checked battery params via RS-485). He said:

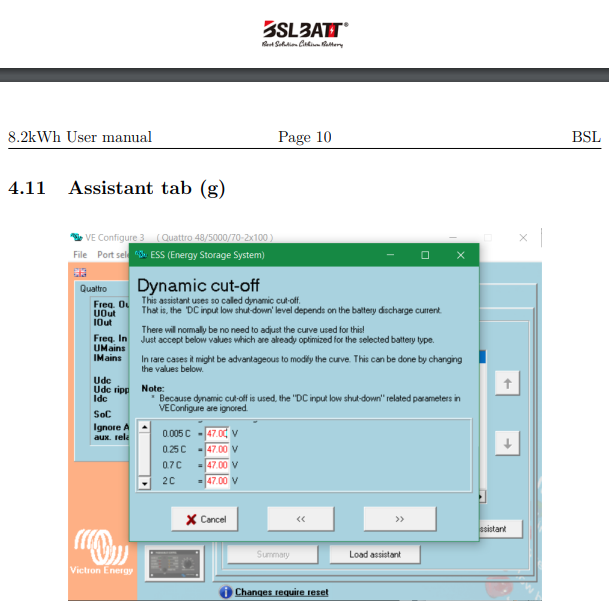

There's a known issue with the MP2 and BSL and FreedomWon batteries. The MP2 has some low voltage offset bug where it would shut down on a battery voltage that isn't actually too low. The issue has been reported to Victron.

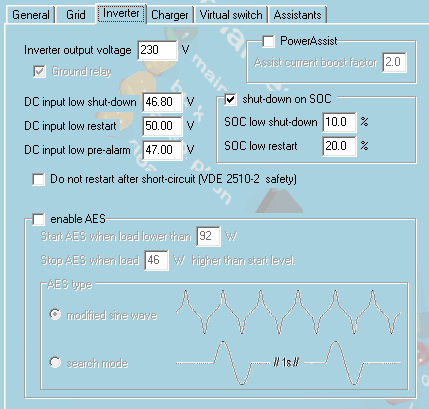

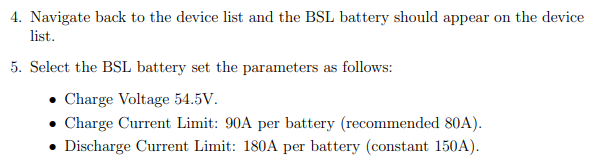

He suggested the installer set the "DC input low shut-down" lower as a workaround for now, until Victron fixes the bug. They set it to 46.80V (at this point the BMS should shut down the battery in any case). They also checked all wiring and replaced all fuses as a precaution.

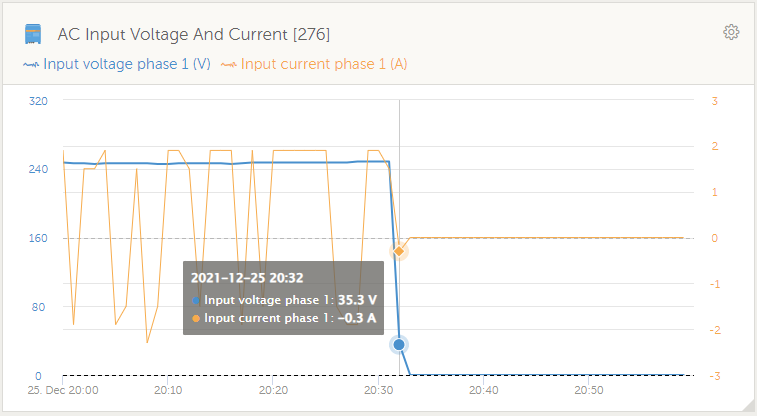

After this, the issue seemed to go away. There was a "Low battery voltage" warning at one point, but no alarm and the system didn't shut down. However, last night when the grid failed (minisub explosion led to panel trip at substation, i.e. probably brownout) the MP2 shut down again for a minute. What is very strange is that there was only a "Low battery voltage" warning - no alarm. I don't understand why it shut down on a warning.

I am skeptical that the cause of the issue is actually a MP2 bug, since this happened on v481 and v490 firmware. Does anyone know about this bug?

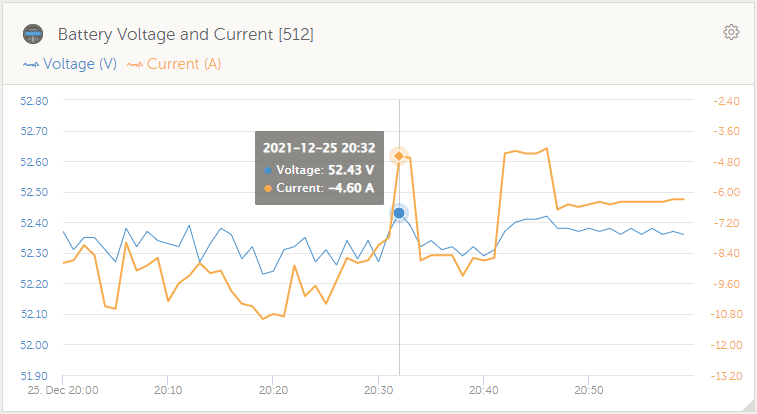

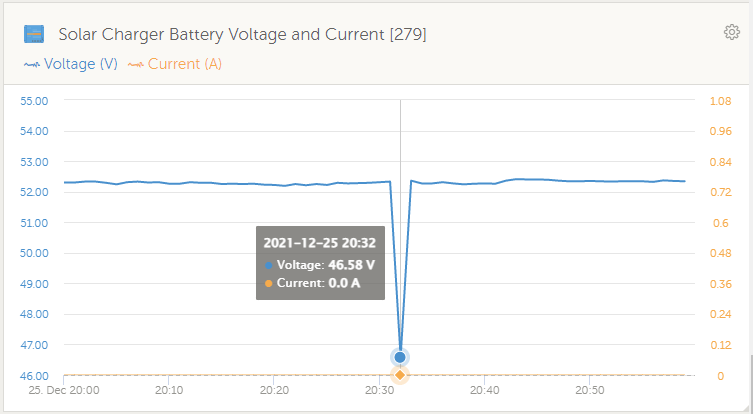

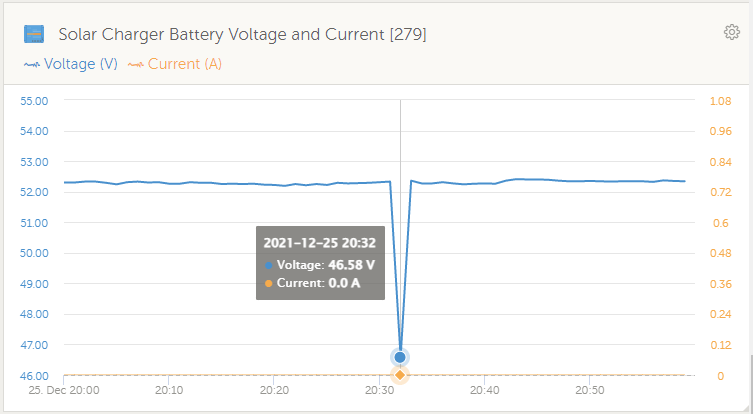

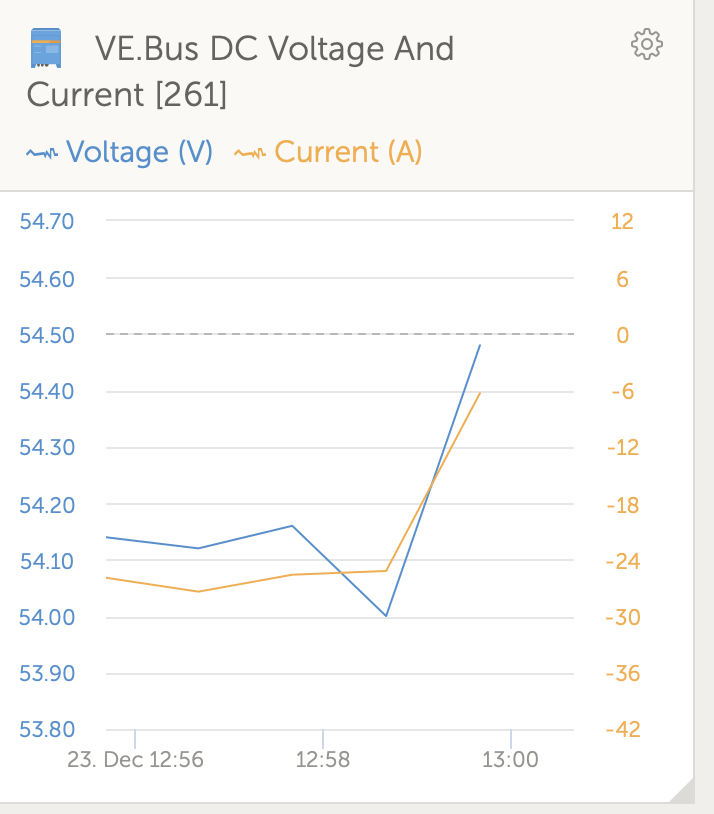

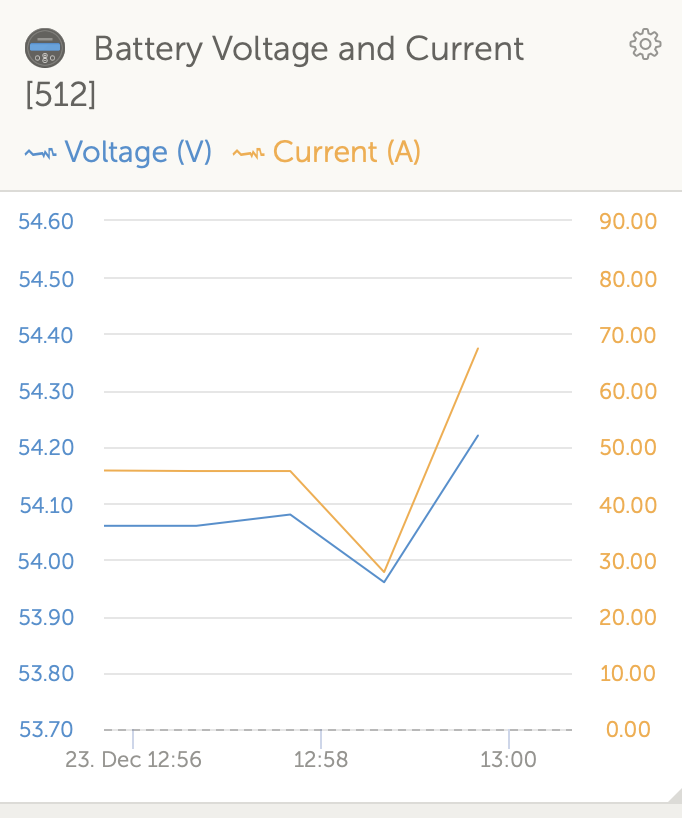

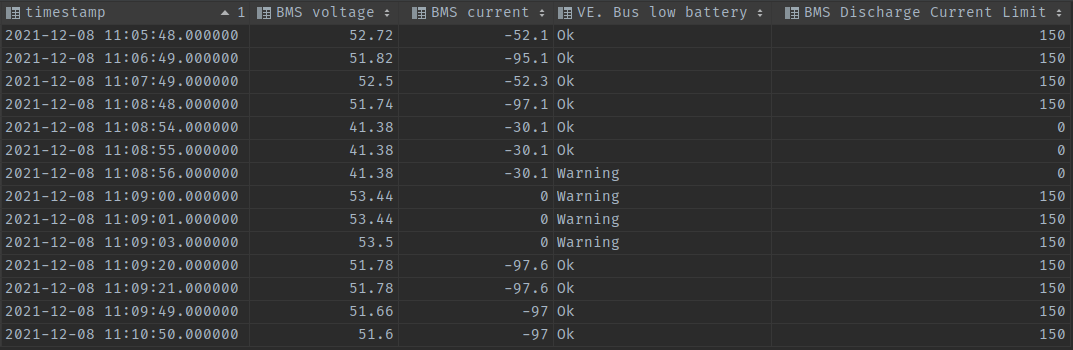

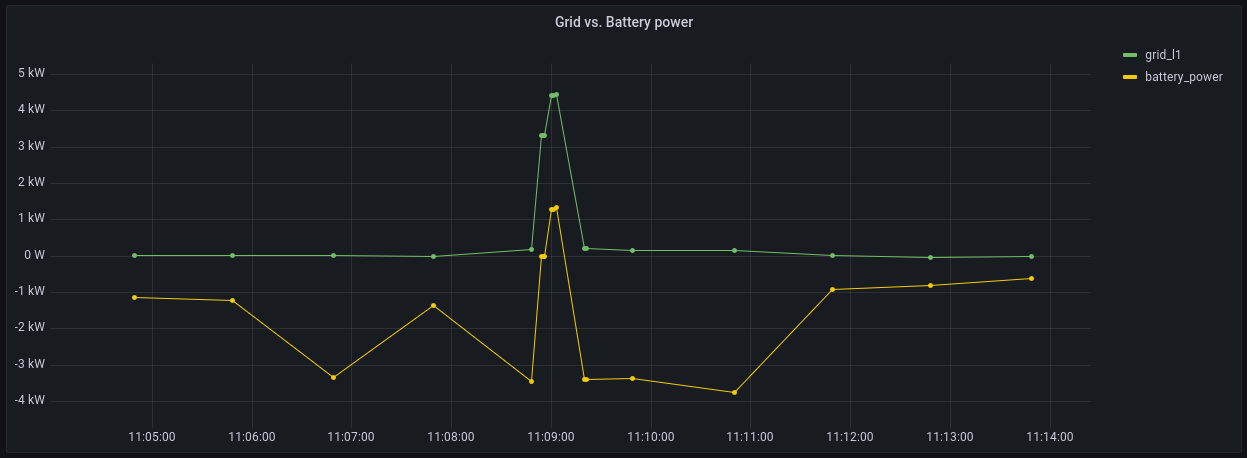

EDIT: I just realized that the MPPT reported a large drop in battery voltage - see the VRM screenshots I replied with. It shows a voltage drop to 46.58V, which is well below the 46.80V DC input low shut-down. I measured the voltage on the battery terminals and at the MPPT with a multimeter. The battery terminals currently measures 53.7V, while the MPPT battery terminals measure 53.9V. Does this seem okay?

My theory of the actual root cause:

- I've seen threads about similar issues, such as this one: MultiPlus II overload on grid failure. One comment that stood out:

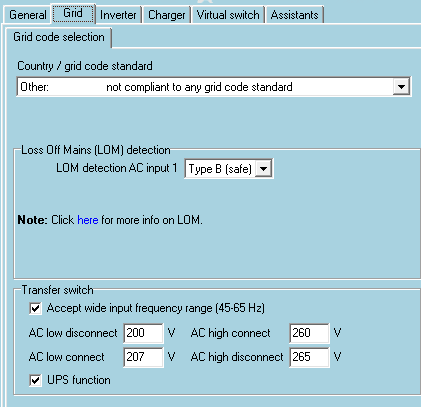

Hi. Solved a similar problem. If you have No grid code set please set you Ac low disconnect to 195vac of even 200ac....low reconnect from 202ac and above. Where i am in Zimbabwe my grid is above 240ac sometimes on failure it browns out as low as 170ac! Unless you install some external capacitors the Mp2 struggles to get into inverter mode from such a low voltage to raise it to 230! HENCE DC RIPPLE SHUTDOWNS..LOW BATTERY LIGHTS.and BMS SAFETY SWITCH OFF..etc.

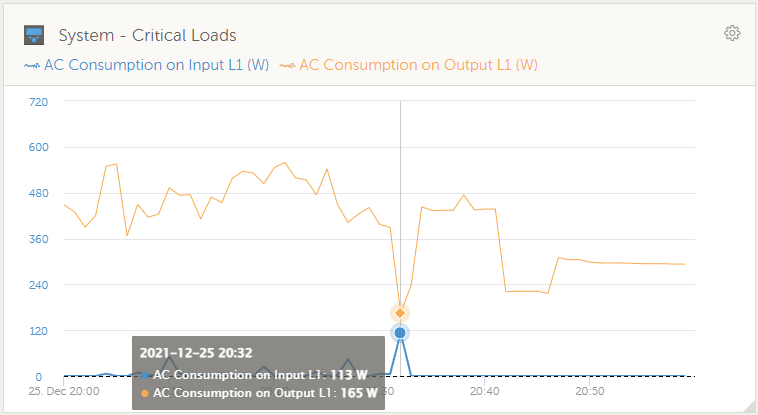

- I have a feeling that when the grid fails (often due to equipment failure) the grid actually experiences a brownout. Then the MP2 tries to follow the voltage down, and finally attempts to switch over to inverter mode, but now the voltage is low enough that it struggles to reach 230V, draws a large current on the battery (thus causing a voltage drop), and shuts off.

- The "AC low disconnect" is currently set at 200V, but maybe this is still too low. The grid runs at anything from 235V - 251V. Should I maybe set the low disconnect to 210V or even higher?

- An external energy meter is beings used via USB (ET112) on the Cerbo. Could it be that it is too slow, and when the grid browns out the MP2 actually follows the grid below the "AC low disconnect"?

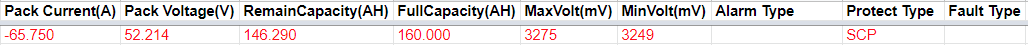

- I checked the BMS warning & alarm history via RS232 and PBMS Tools. There is only one alarm in the log since I purchased the battery, and that's when the "Low battery voltage" warning occurred without the system shutting down. The BMS reported a "SCP" protection (which I assume is Short Circuit Protection). Is this maybe due to a large current being drawn? There was about 4500W that was being drawn at that point, but the battery is 160AH @ 1C, so it should easily be able to handle that.

Does anyone have any ideas or suggestions? The installer has been on site multiple times and they can't figure it out, so I don't know. Should I maybe just insist that they replace the MP2 and battery?

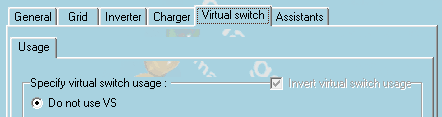

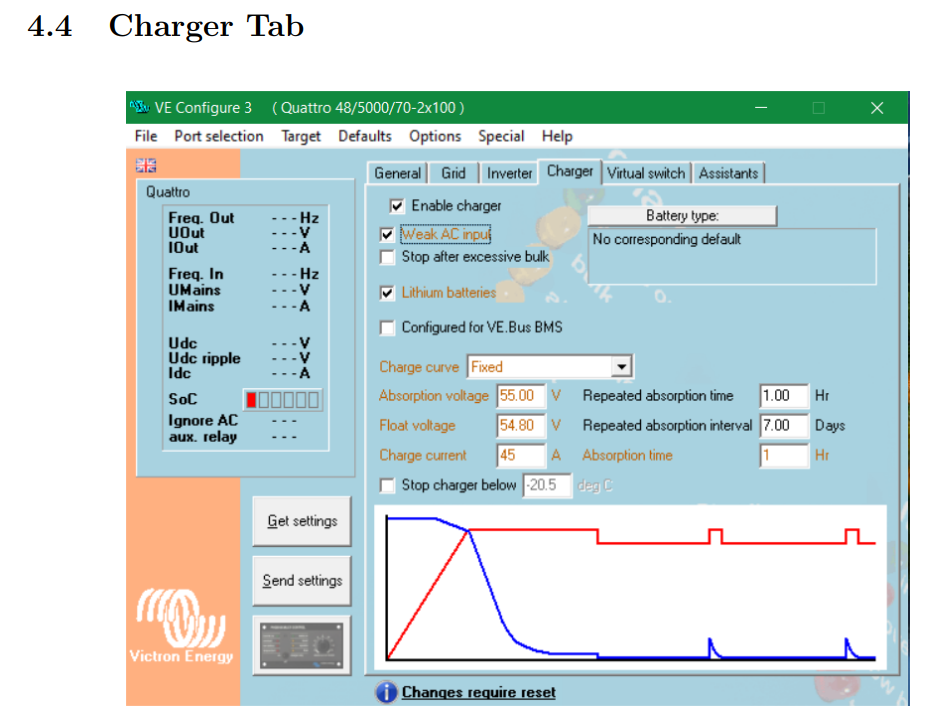

P.S. screenshots of system configuration to follow.