Hi All, I have recently upgraded to 2 Multiplus IIs (48/5000) running in parallel, the main motive was increase the maximum power output, allow faster scheduled charging and to allow the option for a total of 100A transfer switch capacity to allow moving more loads to the AC out.

In early testing of the system I have been getting strange levels of export/import when I would normally expect ESS to keep this around 0. The issue is more common when the ESS system is trying to charge the batteries ie when there is excess solar. I asked this question here which has all my ESS settings etc but I now feel I have a better grasp of what's going on and wanted to start a new discussion as I feel this is impacting more people than just myself.

https://community.victronenergy.com/questions/239228/random-ess-discharge-behaviour.html

I have also read the wiring unlimited and a number of other useful documents such as:

https://www.victronenergy.com/live/ve.bus:manual_parallel_and_three_phase_systems

https://www.victronenergy.com/live/_media/ve.bus:rva_-_theory_on_wiring_large_systems.pdf

https://www.victronenergy.com/upload/documents/Wiring-Unlimited-EN.pdf

Having read a *lot* of forum posts that describe very similar issues and there seems to be 3 common themes that they are advised to look at.

1 - Hardware Revision of the Multi too far apart.

Both of my units were purchased at the same time and are 1 week apart. Running same firmware. v506.

When running as a single unit then ESS works exactly as expected regardless of which Multi is being used.

2 - Mismatch in cable length/thickness - ie impedance is different. Cables too thin/thick etc.

AC In has 6mm2 Twin+Earth at 2m in length running to a sub panel.

DC has 70mm2 Copper at 1.5m length running to Lynx Distributor then 50mm2 at 1.5m to each of the 2 Seplos batteries.

Both multi's have exactly same length/thickness/batch of cables and these have all been remade, cleaned and torqued to spec.

Through testing (see below) I can prove the the cables in my case make no difference.

3 - Make the newest multi the master

I have tried both multi's as master. While this has minimal impact on the forced load tests (export or charging) it does change the behaviour when trying to stick to a 0w setpoint in normal ESS operation.

Master - Slave operation

For ESS/hub4 operation it appears the master takes the desired AC setpoint, compares to its AC readings and regulates to this. It then shares its duty cycle with the slave. As such the Master assumes if it does 50% of the required load then, by virtue of the slave having the same duty cycle it will do the other 50%. Unfortunately this does not seem to be the case in my system. One multi is providing more power for the same duty cycle than the other by a significant amount. Is there any reason the slaves dont sync with the timing of the master but have their own feedback based on a desired share of the setpoint?

** If I have this understanding wrong or someone at victron could correct me that would be great **

All of this leads me to a couple of possible conclusions.

- Significant Hardware/Component difference. My multis are HQ2313 and HQ2314. Could something be different internally them?

- Hardware fault. A failure that is not enough to stop the multi working but is causing a difference in internal resistance.

- Multi or Assistant firmware bug. Could the combination of config, firmware and hardware I have be something that's not working as it should?

If anyone can help me understand why this is happening and why this only really impacts charging regulation that would be very much appreciated. Thank you

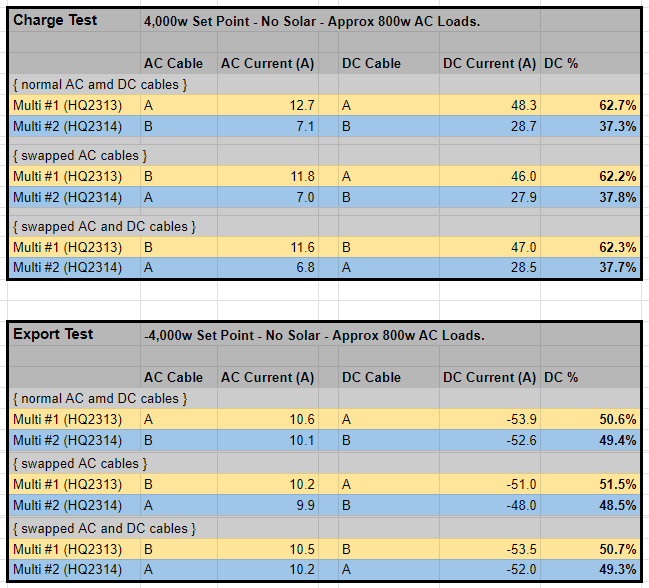

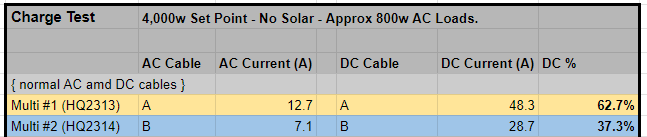

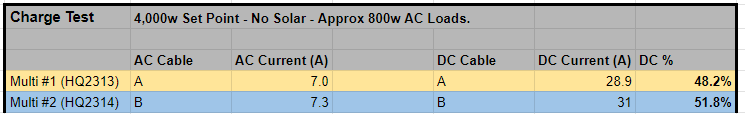

Test methodology: Testing was done by setting the ESS grid setpoint to 4kw to force charging of the batteries. During the test an AC/DC current clamp was used measure amperage on both the AC in cable and DC in cable. The AC and DC cables were marked 'A' and 'B' and swapped in sequence. The export test was done the same way just with -4kw grid set point. Multi #2 was used as the Master throughout the tests. The testing was done with the same current clamp and repeated multiple times to ensure consistency.

Test results summary:

When charging Multi #1 is consistently doing more work. Even with both AC and DC cables swapped the behaviour is almost identical (within 0.5%). This rules out any impedance discrepancies in wiring and connections external to the Multis.

Exporting power is relatively well balanced and as I would expect for a parallel system. Scheduled charging was also tested and was balanced.